wood veneer on plastic

Appearance: Flat

Origin: Linyi, Shandong, China

In Stock: Not Available (Made to Order)

Certifications: ISO9001, SGS, CE

Minimum order quantity: 100pieces

Insect-proof, anti-corrosion, moisture-proof, and fire-resistant (B1)

Low maintenance costs

Easy installation with multiple installation methods to meet various needs.

Delivery time: 15 working days

Package: regular or customized cartons, pearl cotton, wooden case

It is waterproof, soundproof, durable, and available in custom sizes and colors

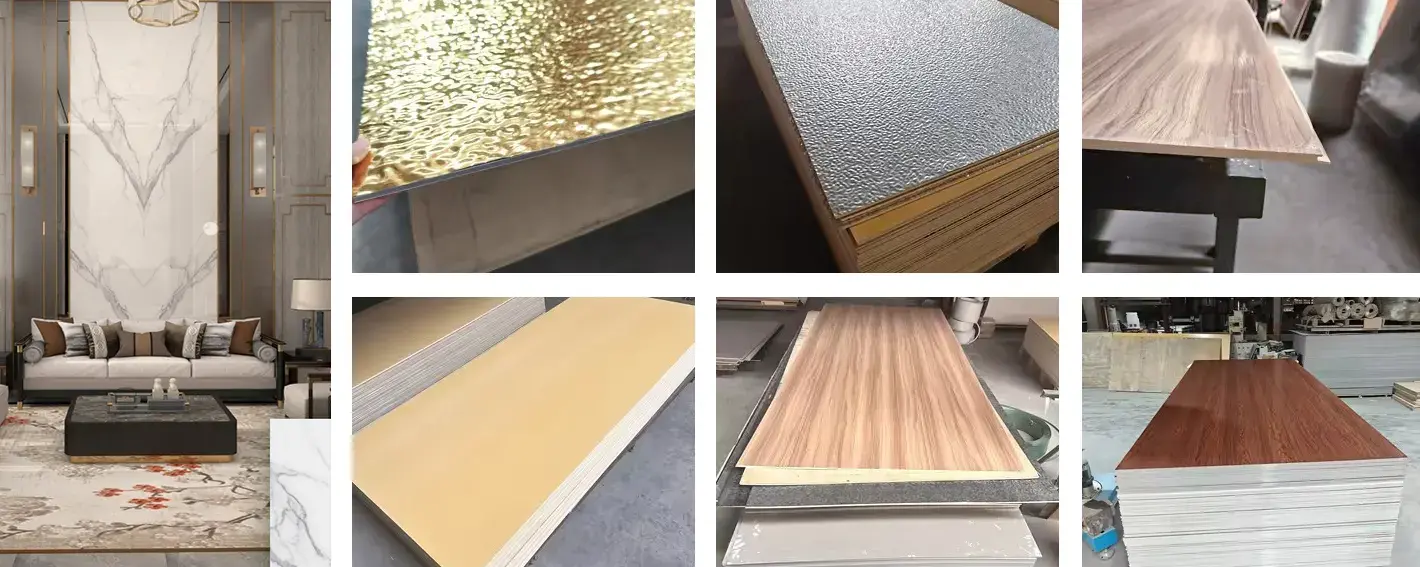

Transform Your Space with Premium Wood Veneer on Plastic Panels

Looking for a stunning yet practical wall solution? Our wood veneer on plastic panels combine the natural beauty of wood grain with the durability of modern materials. These inventive boards offer you the culminate adjust of aesthetics and usefulness. Made with progressed PVC innovation and calcium powder, our boards provide extraordinary execution in any environment. You get all the visual offer of conventional wood without the support cerebral pains. Each board measures 1220mm wide, 5mm thick, and 2900mm long, with custom lengths accessible. Establishment is speedy and direct, making redesign ventures speedier than ever some time recently.

|

|

|

|

Why Choose Wood Veneer on Plastic for Your Next Project?

Unmatched Durability and Performance pvc panel sheet for wall

Our panels resist water, moisture, and stains better than traditional materials. You won't worry about warping, rotting, or mold growth. The dense surface structure provides excellent protection against daily wear and tear. Your investment stays beautiful for years with minimal upkeep required.

Eco-Friendly Innovation

We prioritize your family's health and environmental responsibility. Our wood veneer on plastic contains zero formaldehyde and meets strict E0 emission standards. The manufacturing process utilizes recycled materials, reducing environmental impact. You can breathe easy knowing your walls contribute to a healthier indoor environment.

Versatile Design Options

Select from various wood grain designs, stone surfaces, and strong colors. Each board conveys reliable quality and color coordinating all through your venture. The practical surfaces make advanced spaces that inspire visitors and family alike. Your plan vision gets to be reality with our broad choice.

wood veneer on plastic specification

| Test Part Description: | ||||

| SN ID | Sample No. | SGS Sample ID | Description | |

| SN1 | A1 | CAN24-0283711-0001.C001 | “WPC WALL PANEL” | |

| Remarks: | ||||

| (1)1 mg/kg=1 ppm =0.0001% (2)MDL=Method Detection Limit (3)ND=Not Detected(<MDL) (4)“-“=Not Regulated |

||||

| Volatile Pollutants(VOCs) | ||||

| Test Method: With reference to ISO 16000-9:2024 &ISO 16000-6:2021&ISO16000-3:2022. Testing was performed by Environmental Chamber,followed by sampling using Tenax-TA and DNPH tube,analysis using Thermodesorption System with Gas Chromatography Mass Spectrometry(TDS-GC/MS)and High Performance Liquid Chromatography-DAD(HPLC- DAD). |

||||

| Test Item(s) | CAS No. | Unit(s) | A1 | |

| Test condition | ||||

| Chamber Volume | - | m³ | 0.05 | |

| Storage condition(Temperature) | - | ℃ | 23.2 | |

| Storage condition(Humidity) | - | % | 50.1 | |

| Air Exchange Rate | - | /h | 0.5 | |

| Sample loading | - | m²/m³ | 1.000 | |

| Tenax Sampling Flow | - | mL/min | 200 | |

| Tenax Sampling Time | - | minute(s) | 25 | |

| Tenax Sampling Volume | - | L | 5 | |

| DNPH Sampling Flow | - | mL/min | 300 | |

| DNPH Sampling Time | - | minute(s) | 60 | |

| DNPH Sampling Volume | - | 18 | ||

| MDL_1 | - | μg/m³ | 2.0 | |

| VOCs and Carbonyl Compounds | ||||

| Test Time | - | - | 7th day | |

| Formaldehyde | 50-00-0 | μg/m³ | ND | |

| Acetaldehyde | 75-07-0 | μg/m³ | ND | |

| Toluene | 108-88-3 | μg/m³ | 21.1 | |

| Tetrachloroethene | 127-18-4 | μg/m³ | ND | |

| Xylene | 1330-20-7 | μg/m³ | 127.9 | |

| 1,2,4-Trimethylbenzene | 95-63-6 | μg/m³ | ND | |

| 1,4-Dichlorobenzene | 106-46-7 | μg/m³ | ND | |

| Ethylbenzene | 100-41-4 | μg/m³ | 26.8 | |

| Ethylene Glycol Monobutylether | 111-76-2 | μg/m³ | ND | |

| Styrene | 100-42-5 | μg/m³ | ND | |

| Total Volatile Organic Compounds(TVOC) |

- | μg/m³ | 558.4 | |

| Notes: | ||||

| 1.μg/m³=micrograms per cubic metre | ||||

| Evaluation according to Decree 2011-321 relative to the labeling of construction products,floor or wall coverings and paints and lacquers concerning their emission of volatile pollutants | ||||

| Classes | C | B | A | A+ |

| Formaldehyde | >120 | <120 | <60 | <10 |

| Acetaldehyde | >400 | <400 | <300 | <200 |

| Toluene | >600 | <600 | <450 | <300 |

| Tetrachloroethylene | >500 | <500 | <350 | <250 |

| Xylene | >400 | <400 | <300 | <200 |

| 1,2,4 Trimethylbenzene | >2000 | <2000 | <1500 | <1000 |

| 1,4-Dichlorobenzene | >120 | <120 | <90 | <60 |

| Ethylbenzene | >1500 | <1500 | <1000 | <750 |

| Ethylene Glycol Monobutylether | >2000 | <2000 | <1500 | <1000 |

| Styrene | >500 | <500 | <350 | <250 |

| TVOC | >2000 | <2000 | <1500 | <1000 |

| Remark: | ||||

| Unit:ug/m³ | ||||

| Calculated Result =SER/q | ||||

| The concentrations of exposition are calculated in a conventional reference room of a total volume (V)of 30m³,in which is applied a rate of air renewal(n)of 0.5h-¹and which dimensions are specified here below: | ||||

| Surface (S) (m²) |

Load rate (L=SN)(m²/m³) |

Surface specific emission output(q=n/L)(m³.m-².h-¹) |

||

| Floor | 12 | 0.4 | 1.25 | |

| Ceiling | 12 | 0.4 | 1.25 | |

| One door | 1.6 | 0.05 | 10 | |

Perfect Applications for Every Space

Kitchen and Bathroom Excellence

Moisture-rich environments demand special materials. Our panels handle humidity without deterioration or damage. Cleaning becomes effortless with simple damp cloth maintenance. You enjoy beautiful walls that withstand cooking steam and bathroom moisture daily.

Living Areas and Bedrooms

Create stunning accent walls and complete room makeovers easily. The panels provide excellent acoustic properties for quieter, more comfortable spaces. Installation typically completes in just a few days for average-sized rooms. Your home transformation happens faster than traditional renovation methods.

Commercial Spaces

Restaurants, offices, and retail locations benefit from our durable panels. The professional appearance enhances brand image and customer experience. Maintenance costs stay low while visual impact remains high. Your business space looks premium without premium maintenance requirements.

Technical Excellence You Can Trust

Superior Material Composition

Our panels combine thermoplastic PVC with calcium powder and specialized additives. The high-temperature extrusion process ensures consistent quality and strength. Water absorption remains under 0.5%, far lower than traditional wood materials. You get reliable performance backed by rigorous testing and certification.

Professional Installation Made Simple

The installation process requires basic carpentry skills and standard tools. High-strength adhesive creates secure, long-lasting bonds with proper substrates. Remember to leave 3-5mm expansion joints between panels for optimal results. Your contractor appreciates the straightforward installation process that saves time and labor costs.

Quality Control Standards

Every panel undergoes comprehensive inspection for flatness, color consistency, and dimensional accuracy. Our CE, SGS, and ISO certifications demonstrate commitment to international quality standards. The B1 fire rating provides additional safety assurance for your project. You receive products that meet the highest industry benchmarks.

Smart Investment Benefits

Long-Term Value

Our 10-year quality guarantee protects your investment with confidence. Maintenance costs stay minimal compared to traditional wood or painted surfaces. The panels resist fading, scratching, and moisture damage over time. Your renovation investment pays dividends through lasting beauty and performance.

Quick Project Completion

Most installations complete within days rather than weeks. No lengthy drying times or multiple coating applications required. You return to normal life faster with less disruption. The efficiency saves both time and money on labor costs.

Customer Success Stories

Homeowners consistently praise the odor-free installation and rapid occupancy timeline. Many families move back into renovated spaces within one week of completion. Commercial clients appreciate the easy maintenance and professional appearance. The overwhelmingly positive feedback reflects our commitment to customer satisfaction and product excellence.

Exhibition

Packing

FAQ

Minimum Order Quantity (MOQ) Q: What is your minimum order quantity?

A: We understand that global trade requires flexibility. Our standard MOQ is 500 meters, applicable to mixed product orders.

Packaging: How do you package WPC polyethylene panels to ensure they arrive intact?

A: We attach great importance to packaging to prevent damage during transportation.

Wood Veneer Series: Adopt a customized shockproof packaging structure. Each panel is covered with a PVC protective film on the surface, fully wrapped around the edges with high-elasticity EPE foam, and packed in wooden crates.

Custom packaging is available upon request to meet specific logistics or sustainability requirements.

DeliveryQ: What is the average lead time?

A: Standard orders require 15–20 days after confirmation. For large-scale or customized orders, we will provide a detailed production plan in advance and keep you updated throughout the entire process.

Why Choose Us?

1. Global Experience: We have supplied products to over 50 countries, adapting to diverse market demands.

2. Transparent Communication: We keep you informed at every step from order placement to shipment.

3. Commitment to Quality: Every batch of goods undergoes strict quality control inspections before leaving the factory.

Ready to Transform Your Space?

Our wood veneer on plastic panels offers the perfect solution for modern renovation needs. Contact our expert team today to discuss your project requirements and design goals. We provide free samples to ensure perfect color and texture matching. Custom sizing options accommodate unique architectural requirements and creative designs.

Get started with your transformation today. Contact us at dingyue@dywpcpvcpanel.com for personalized assistance and free samples.

Your dream space awaits with our premium wood veneer panels—where beauty meets performance.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”