Certification

Shandong Dingyue: Concise Analysis of Product Certifications and Core Categories

Focusing on "environmentally friendly decorative materials" as its core, Shandong Dingyue relies on three major certifications (CE, SGS, and ISO) to consolidate the compliance and quality of its main products, including PVC wall panels, WPC wall panels, bamboo charcoal wood veneer panels, and outdoor ecological wood. The key product information is as follows:

CE Certification: Adapting to the International Market and Highlighting Product Scenario Performance

(I) Indoor Products

1. Full Series of WPC Wall Panels: Covering 160mm basic model, 150mm thin model (148×10mm/151×8mm), 150C narrow model (146×7mm), 170 eight-track model (160×15.5mm), 195B medium-thickness model (192×14mm), 195 double-reinforced model (192×12mm), and 159 thick-wall model (150×26mm). Its formaldehyde emission is ≤ 0.03mg/m³ (far lower than the EU E1 class standard), with no cracks in impact resistance tests and no deformation at 70℃. The 195 double-reinforced model has become a core product for high-end hotels in the EU.

2. Indoor PVC Wall Panels: Waterproof and moisture-proof (water absorption rate < 1% after 24-hour immersion), termite-proof, and resistant to stains such as soy sauce and vinegar. It solves the problem of mold growth in humid environments and is directly supplied to the EU residential market.

3. Bamboo Charcoal Wood Veneer Panels: Featuring natural wood grain on the surface (no painting required) and a VOC emission of ≤ 0.5mg/(m²・h), it is suitable for EU household wardrobe door panels and children's room feature walls, and has become a preferred choice for high-end light luxury home decoration overseas.

(II) Outdoor Products

1.Outdoor PVC Wall Panels: Focusing on anti-aging and sun protection. It has a color fading rate < 3% after 1000-hour UV aging test, no cracking in the temperature cycle test from -30℃ to 70℃, and no blistering after 72-hour rain test. It is suitable for high-temperature areas in the Middle East and cold regions in Northern Europe, and is used for courtyard walls of resorts in Southeast Asia.

2. Outdoor Ecological Wood: Including flooring (140×20mm/140×22mm/140×25mm) and wall panels (219×26mm). It has anti-slip performance (friction coefficient ≥ 0.6) and no damage when a 1kg weight falls from a height of 1m. It solves the problem that traditional solid wood is prone to moisture and decay, and is used for park boardwalks in the EU

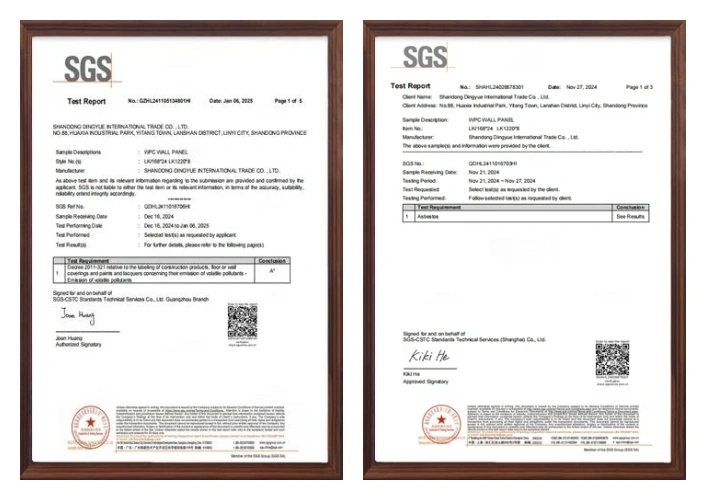

II. SGS Certification: Data Proves the Strong Strength of Products

1. WPC Wall Panels (159 thick-wall model): Formaldehyde emission < 0.01mg/m³ and heavy metal leaching < 0.001mg/L (far lower than the national standard), eliminating concerns about decoration pollution.

2. Bamboo Charcoal Wood Veneer Panels: Tested to have no peculiar smell and strong decorative effect of wood grain, making it a preferred material for maternal and child rooms and elderly rooms.

3. Indoor-Outdoor Universal PVC Wall Panels: With a water absorption rate of 0.8% after 24-hour immersion (waterproof) and no obvious scratches after 500 cycles of friction (abrasion-resistant), it is suitable for kitchens, bathrooms, and corridors.

4. WPC Wall Panels (195 double-reinforced model): No deformation under 150kg load, and no blistering after 72 hours in an environment with a temperature of 40℃ and humidity of 90%, making it suitable for hotel lobbies and humid areas.

5. Outdoor Ecological Wood Boardwalk Panels: The mechanical performance retention rate is ≥ 90% after 1500-hour UV aging test (service life over 15 years), and no rusting after 500-hour salt spray test, suitable for outdoor use in coastal areas.

III. ISO Certification: Ensuring Consistency in Product Quality

1. Production Control (Taking WPC Wall Panels as an Example): Each batch of raw materials undergoes pre-testing by SGS; the 170 eight-track model is produced with parameters of 180±2℃ (temperature), 0.8MPa (pressure), and 30±5s (molding time), with splicing groove deviation ≤ 0.1mm; no less than 5% of each batch is sampled to test dimensions, flatness, and color (e.g., the deviation of 150mm thin model is ≤ 0.2mm).

2. Quality Implementation: For an EU order of 100,000㎡ 150mm thin WPC wall panels (151×8mm), the color difference ΔE is < 1.0 (invisible to the naked eye), with a reorder rate of 90%; each product has a unique traceability code, enabling the identification of after-sales problems within 48 hours.

IV. Synergy Between Products and Certifications: Covering All Scenarios

|

Product Type |

Key Performance (Certified by Certifications) |

Domestic Application Scenarios |

International Application Scenarios |

|

Indoor WPC Wall Panels |

Near-zero formaldehyde emission, anti-deformation, abrasion resistance |

Residential bedrooms, high-end hotels |

EU residences, Southeast Asian apartments |

|

Outdoor PVC Wall Panels |

UV resistance, high-low temperature resistance, corrosion resistance |

Courtyard walls, outdoor corridors |

Resorts in the Middle East, villas in Northern Europe |

|

Bamboo Charcoal Wood Veneer Panels |

Natural wood grain, no peculiar smell |

Feature walls of maternal and child rooms/elderly rooms |

EU household wardrobe door panels, high-end boutique homestays |

|

Outdoor Ecological Wood |

Anti-slip, anti-aging, salt spray resistance |

Park boardwalks, landscape walls |

Parks in Europe and America, coastal villa flooring |

Indoor products rely on certifications to eliminate environmental concerns, outdoor products use certifications to enhance weather resistance, and all product categories ensure quality through certifications. This not only meets domestic health needs but also conforms to international compliance standards, achieving improved product competitiveness.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”