Guide to Selecting Fire-Resistant Veneer Materials

Fire safety is the most important thing to think about when designing and building interiors. By choosing the right fire-resistant wood materials, you can make your area much safer and last longer. This complete guide will look into the world of fire-resistant veneers, focusing on new choices such as PET film wood veneer. This article will give you useful information to help you make smart choices about your next job, whether you're a builder, an interior designer, or a property owner.

Understanding Fire-Resistant Veneer Materials

Modern building and interior design depend on surface materials that don't catch fire. These special layers are made to withstand high temperatures and slow the spread of fires, giving people time to get out of the building and help fight the fire in case of an emergency.

The Importance of Fire Resistance in Veneers

Fire safety must be taken into account when designing a building and choosing its materials. Fire-resistant woods have many advantages, such as:

• Better safety for people living there

• Less damage to property in case of fire

• Following all building rules and codes

• Possible insurance perks

• Peace of mind for people who own and handle properties

From all the choices that are out there, PET film wood veneer has become the best choice for people who want both looks and safety. The natural beauty of wood is combined with improved fire-resistant qualities in this new material, which makes it a great choice for many uses.

Types of Fire-Resistant Veneer Materials

There are a few different kinds of fire-resistant wood on the market:

• Mineral-based veneers

• Fire-resistant wood veneers

• Composite veneers with fire-resistant chemicals

• Metal veneers

• PET film wood veneers

You can tell each type apart by its own set of traits, pros and cons. One thing that makes PET film wood veneer stand out from other choices is that it is resistant to fire, lasts a long time, and looks good.

Key Properties of Fire-Resistant Veneers

When looking at fire-resistant veneers, like PET film wood veneer, keep these important things in mind:

• Index of flame spread

• Index of smoke growth

• Index of ignition resistance

• Index of heat release

• Index of burning products' toxicity

Knowing about these features will help you choose the best fire-resistant finish for your needs.

Advantages of PET Film Wood Veneer in Fire-Resistant Applications

Because it has a unique set of qualities, PET film wood veneer has become very popular in the world of fire-resistant products. This is a great choice for architects, designers, and builders because it has many benefits.

Superior Fire Resistance

The engineering behind PET film wood veneer makes it very resistant to fire without sacrificing looks. Some important characteristics are:

• High burning temperature

• Low flame spread rate

• Low smoke production

• Self-extinguishing qualities

Because of these qualities, PET film wood veneer is a great choice for places like businesses, restaurants, and public areas where fire safety is very important.

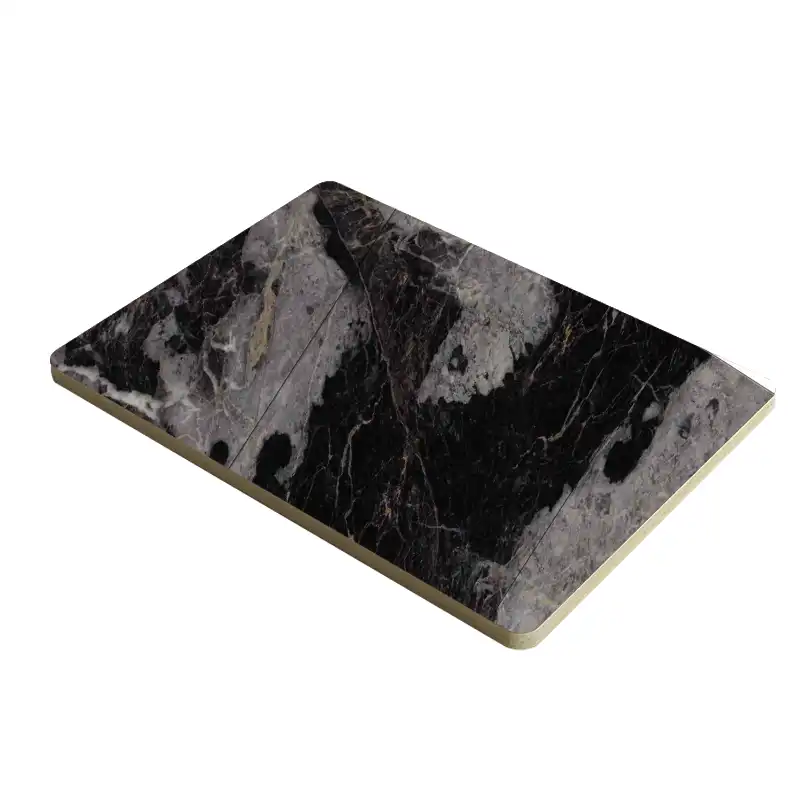

Aesthetic Versatility

The ability of PET film wood veneer to resemble real wood while providing better fire protection is one of its most important benefits. Because it's so flexible, designers can:

• Pick from a lot of different wood grain patterns and colors

• Get a high-end, natural wood look without sacrificing safety

• Make finishes that are smooth and uniform across big areas

• Combine the warmth of wood with today's rules about fire safety

PET film wood veneer is a good choice for both classic and modern design plans because it can look good in both.

Durability and Longevity

In addition to being fire-resistant, PET film wood veneer is very long-lasting:

• Not easily scratched, dented, or hit.

• It doesn't absorb water easily, so it can be used in damp places

• Easy to clean and maintain

• Long-lasting performance, so you don't have to buy new ones as often

These features make PET film wood veneer last a long time, so it keeps looking good and isn't likely to catch fire. This makes it a good choice for long-term projects.

Selecting the Right Fire-Resistant Veneer for Your Project

There are a lot of things that need to be carefully thought through when choosing the right fire-resistant veneer, like PET film wood veneer. Making the right choice for your job is important, and this part will walk you through the decision process.

Assessing Your Project's Fire Safety Needs

Before choosing a fire-resistant surface, it's important to look at the fire safety needs of your project:

• Look over the local building codes and rules

• Think about the type of people who will be living in and using the building

• Look at the space's general fire safety plan

• Figure out what fire resistance scores are needed in different areas

Knowing about these things will help you choose a finish that meets or goes beyond the fire safety standards that are needed. With its improved fire-resistant qualities, PET film wood veneer is often a great choice for meeting strict safety standards.

Evaluating Performance Certifications

If you're looking for fire-resistant veneers, like PET film wood veneer, pay close attention to the following performance certifications:

• Look for materials that have been tested to ASTM E84 or similar standards

• Make sure they meet national and international fire safety standards

• Think about getting extra certifications for certain uses, like sea or flight

The fire performance approvals and test results for their goods should be readily available from a reliable PET film wood veneer supplier.

Considering Aesthetics and Design Flexibility

Even though fire safety is the most important thing, how the surface looks is also very important. PET film wood veneer is a great way to combine safety and style:

• Look at the different wood grain patterns and colors that are available

• Think about how the veneer will fit in with your general design.

• Check to see if the wood can be used to make big, uniform uses.

• Think about how the style will look in the long run and whether it can be updated.

Because PET film wood veneer is so flexible, designers can get the look they want while still meeting high safety standards.

Factoring in Environmental Considerations

In today's eco-friendly world, choosing products that are good for the earth is important. When looking at PET film wood veneer and other fire-resistant choices, you should think about:

• How easily the product can be recycled and thrown away at the end of its useful life

• Effects on VOC pollution and indoor air quality

• The manufacturer's promise to use environmentally friendly methods of production

As an environmentally friendly option for fire-resistant uses, many PET film wood veneer goods are made with long-term use in mind.

Conclusion

It is very important to choose the right fire-resistant wood material for your projects to make sure they are safe, meet regulations, and look good. PET film wood veneer stands out as a flexible and high-performance choice that looks like real wood and is very resistant to fire. By carefully thinking about the specific needs of your project, looking at performance ratings, and finding a balance between safety and looks, you can make an informed choice that makes your space safer and more attractive.

During the decision process, keep in mind that talking to knowledgeable professionals and trustworthy sources like Dingyue can help you make the best choice for your fire-resistant wood needs. With the right choice of materials, you can make places that are not only beautiful to look at but also put people's safety and health first.

FAQ

What is PET film wood veneer?

A: A new kind of artistic material called PET film wood veneer blends the look of real wood with the strength of plastic. Using a high-temperature molding method, PVC and calcium powder are combined to make it. The finished product is both aesthetically pleasing and useful.

What are some benefits of PET film wood veneer over real wood and clay tiles?

A: PET film wood veneer is more immune to water, wetness, insects, and rot than pure wood for furniture. It doesn't crack or bend, doesn't need to be painted, is simple to put together, and doesn't need much upkeep. Compared to clay tiles, it has a softer feel, can be put down faster without cement glue, doesn't slip as easily, and doesn't crack as easily in cold weather.

Where does PET film wood veneer get used most often?

A: PET film wood veneer is flexible and can be used in many places, such as on the walls of your living room or bedroom, as a TV background, in your kitchen, bathroom, on a balcony, in your basement, on your ceiling, or in a business space like a restaurant, office, or shop.

Experience the Excellence of PET Film Wood Veneer | Dingyue

At Dingyue, we're proud of our dedication to providing high-quality PET film wood veneer items that meet the strictest standards for fire safety and good looks. Our state-of-the-art 30,000 m² production center and 150+ advanced production lines, along with our more than 10 years of experience in the field, make sure that quality is always high and customization is quick and easy. Our creative research and development team is always coming up with new solutions that are safe, flame-resistant, and long-lasting and that meet a wide range of international standards.

Dingyue's PET film wood veneer is reliable, approved, and looks beautiful. It will take your projects to new heights. Get in touch with us at dingyue@dywpcpvcpanel.com to talk about how our PET film wood veneer goods can make your next project safer and look better.

References

1. National Fire Protection Association. (2021). "Fire-Retardant-Treated Wood and Fire-Retardant Coatings for Building Materials." NFPA Handbook, 20th Edition.

2. Lowden, L. A., & Hull, T. R. (2013). "Flammability behaviour of wood and a review of the methods for its reduction." Fire Science Reviews, 2(1), 4.

3. Östman, B., & Tsantaridis, L. (2017). "Fire retardant treated wood products - Properties and uses." Wood Material Science & Engineering, 12(5), 328-335.

4. White, R. H., & Dietenberger, M. A. (2010). "Fire safety of wood construction." In Wood handbook: Wood as an engineering material (pp. 18-1 - 18-22). Forest Products Laboratory.

5. Hirata, T., Kawamoto, S., & Nishimoto, K. (1991). "Thermogravimetry of wood treated with fire-retardants." Wood Science and Technology, 25(6), 457-468.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”