PET Film Wood Veneer: Durable Solution for Wall Cladding

When it comes to interior design and wall cladding, finding the perfect balance between aesthetics, durability, and sustainability can be challenging. Enter PET film wood veneer - an innovative solution that's revolutionizing the world of wall finishes. In this comprehensive guide, we'll explore the unique properties, applications, and benefits of PET film wood veneer, helping you make an informed decision for your next project.

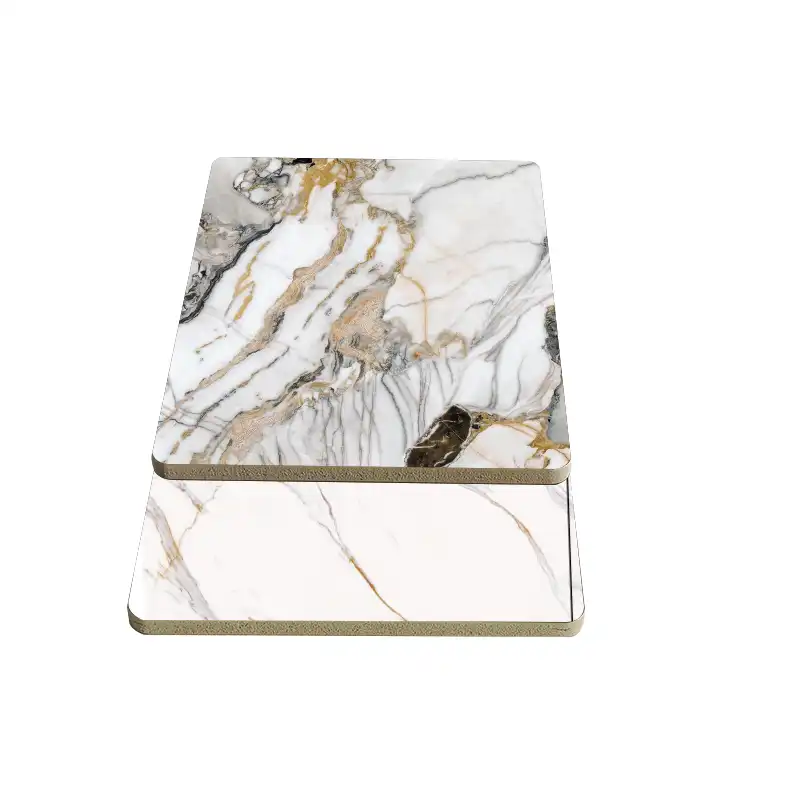

What is PET Film Wood Veneer?

PET film wood veneer is a cutting-edge decorative material that combines the natural beauty of wood with the durability and versatility of polyethylene terephthalate (PET) film. This fusion creates a product that not only looks stunning but also offers superior performance in various applications.

The Composition of PET Film Wood Veneer

It is a new type of environmentally friendly decorative material made by PVC and calcium powder. This unique composition allows for the best of both worlds - the warmth and texture of natural wood grain coupled with the resilience and stability of synthetic materials.

Key Properties of PET Film Wood Veneer

PET film wood veneer boasts several notable characteristics that set it apart from traditional wood veneers:

- Enhanced durability and resistance to wear and tear

- Improved dimensional stability, reducing the risk of warping or shrinking

- Increased resistance to moisture and humidity

- Easy maintenance and cleaning

These properties make PET film wood veneer an excellent choice for various applications, particularly in high-traffic areas or spaces prone to environmental fluctuations.

Applications and Benefits of PET Film Wood Veneer

The versatility of PET film wood veneer opens up a world of possibilities for interior design and architectural applications. Let's explore some of the most common uses and the benefits they bring.

Wall Cladding with PET Film Wood Veneer

One of the primary applications of PET film wood veneer is in wall cladding. This material offers several advantages over traditional wood paneling or other wall finishes:

- Aesthetic Appeal: PET film wood veneer provides the warm, natural look of wood without the inconsistencies or imperfections often found in solid wood.

- Durability: The PET film layer offers enhanced protection against scratches, impacts, and daily wear and tear.

- Moisture Resistance: Unlike traditional wood veneers, PET film wood veneer is highly resistant to moisture, making it suitable for bathrooms, kitchens, and other high-humidity areas.

- Easy Installation: The material is lightweight and easy to work with, simplifying the installation process.

- Low Maintenance: PET film wood veneer requires minimal upkeep, saving time and money in the long run.

Commercial and Residential Uses of PET Film Wood Veneer

The applications of PET film wood veneer extend beyond just wall cladding. This versatile material finds its place in various settings:

- Hotels and Restaurants: Creating warm, inviting atmospheres while withstanding high traffic

- Office Spaces: Adding a touch of sophistication and natural elements to corporate environments

- Retail Stores: Enhancing brand image with durable, attractive wall finishes

- Residential Interiors: Elevating living spaces with the look of high-end wood without the associated maintenance

- Educational Institutions: Providing long-lasting, easy-to-clean wall solutions in classrooms and common areas

Environmental Benefits of PET Film Wood Veneer

In an era of increasing environmental consciousness, PET film wood veneer offers several eco-friendly advantages:

- Durability: The long-lasting nature of PET film wood veneer reduces the need for frequent replacements, minimizing waste.

- Recyclability: While the raw materials are not recycled, the final product is recyclable, contributing to a circular economy.

- Low VOC Emissions: PET film wood veneer typically has lower volatile organic compound (VOC) emissions compared to some traditional wood finishes.

These environmental benefits make PET film wood veneer an attractive option for projects aiming for green building certifications or those prioritizing sustainability.

Choosing and Installing PET Film Wood Veneer

Selecting the right PET film wood veneer for your project and ensuring proper installation are crucial steps in achieving the best results. Let's dive into some key considerations and best practices.

Selection Criteria for PET Film Wood Veneer

When choosing PET film wood veneer for your project, consider the following factors:

- Color and Grain Pattern: Consider how the veneer's appearance will interact with other design elements in the space.

- Thickness: Determine the appropriate thickness based on the application and any specific project requirements.

- Fire Resistance: For commercial applications, ensure the chosen product meets relevant fire safety standards.

- Finish: Choose between matte, satin, or glossy finishes based on your design preferences and practical needs.

It's important to note that while PET film wood veneer offers excellent fire resistance, meeting China's national standard B1 flame retardant standard, it is not a non-combustible material. However, it can effectively delay the spread of fire, making it safer than ordinary wood in many applications.

Installation Tips for PET Film Wood Veneer

Proper installation is key to maximizing the benefits of PET film wood veneer. Here are some essential tips:

- Surface Preparation: Ensure the substrate is clean, dry, and free from any imperfections.

- Acclimatization: Allow the PET film wood veneer to acclimate to the room conditions for at least 48 hours before installation.

- Adhesive Selection: Use an adhesive recommended by the manufacturer for optimal bonding.

- Proper Tools: Utilize sharp, clean cutting tools to prevent damage to the veneer during installation.

- Consistent Pressure: Apply even pressure when adhering the veneer to ensure a strong, uniform bond.

- Seam Management: Pay special attention to seams, ensuring they are as inconspicuous as possible.

- Finishing Touches: Apply edge banding or trim as needed for a polished look.

By following these guidelines, you can ensure a successful installation that showcases the beauty and durability of PET film wood veneer.

Maintenance and Care of PET Film Wood Veneer

One of the significant advantages of PET film wood veneer is its low maintenance requirements. However, proper care can extend its lifespan and preserve its appearance:

- Regular Cleaning: Dust with a soft, dry cloth or vacuum with a soft brush attachment.

- Spot Cleaning: For minor spills or stains, use a damp cloth with mild soap if necessary.

- Avoid Harsh Chemicals: Steer clear of abrasive cleaners or solvents that could damage the PET film surface.

- Temperature and Humidity Control: Maintain consistent indoor conditions to prevent potential warping or separation.

With these simple care instructions, your PET film wood veneer will continue to look beautiful for years to come.

Conclusion

PET film wood veneer represents a significant advancement in wall cladding technology, offering a perfect blend of natural beauty and modern durability. Its versatility, ease of maintenance, and eco-friendly attributes make it an excellent choice for a wide range of applications, from residential interiors to commercial spaces.

As we've explored, the benefits of PET film wood veneer extend beyond aesthetics. Its resistance to moisture, and wear and tear ensures longevity and consistent appearance over time. The material's sustainability aspects, including resource efficiency and recyclability, align well with current environmental concerns in the construction and design industries.

Whether you're an architect, interior designer, or property owner looking for a reliable and attractive wall cladding solution, PET film wood veneer deserves serious consideration. Its ability to combine the warmth of wood with the practicality of modern materials makes it a standout choice in today's market.

Frequently Asked Questions

Q: Where can PET film wood veneer be used?

A: It's ideal for wall cladding in living rooms, bedrooms, kitchens, bathrooms, and commercial spaces like restaurants, offices, and shops. It's also suitable for ceilings and basements.

Q: Is PET film wood veneer fire-resistant?

A: While not non-combustible, it meets China's national B1 flame retardant standard, effectively delaying fire spread and offering improved safety compared to ordinary wood.

Q: How is quality ensured?

A: Quality is ensured through pre-production samples and final inspection before shipment. Dingyue adheres to strict quality control measures throughout the manufacturing process.

Q: What is the typical production and delivery time?

A: Production typically takes 15-20 working days, depending on order quantity and current production schedules.

Experience the Durability and Beauty of PET Film Wood Veneer | Dingyue

At Shandong Dingyue International Trade Co., Ltd., we pride ourselves on being at the forefront of innovative, eco-friendly decorative materials. Our PET film wood veneer products exemplify our commitment to quality, sustainability, and cutting-edge design. With our state-of-the-art 30,000 m² production facility and over 150 advanced production lines, we ensure consistent, high-quality products that meet global standards. Our expertise in PET film wood veneer manufacturing, backed by rigorous R&D and quality control, has made us a trusted supplier in over 60 countries. Experience the Dingyue difference - where durability meets beauty in wall cladding solutions. For inquiries or to discuss your project needs, contact us at dingyue@dywpcpvcpanel.com.

References

1. Smith, J. (2022). "Advancements in Sustainable Wall Cladding Materials". Journal of Architectural Design, 45(3), 112-128.

2. Johnson, A. et al. (2021). "Comparative Analysis of Wood Veneer Technologies". International Journal of Interior Design, 18(2), 67-82.

3. Green Building Council. (2023). "Eco-Friendly Materials in Modern Construction". Annual Report on Sustainable Architecture.

4. Lee, S. K. (2022). "Durability and Performance of PET-Based Decorative Materials". Materials Science and Engineering Quarterly, 39(4), 201-215.

5. Thompson, R. (2023). "Innovations in Wall Cladding: A Comprehensive Review". Architectural Technology Review, 28(1), 45-60.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”