8mm PET film wood veneer is becoming more common because it looks great, lasts a long time, and is affordable for use in current building projects. This new cosmetic material uses polyethylene terephthalate technology and lifelike wood grain designs. It works better than traditional veneer choices and meets the strict environmental standards that today's building industry requires.

Understanding 8mm PET Film Wood Veneer: Overview and Key Features

Product Composition and Technology

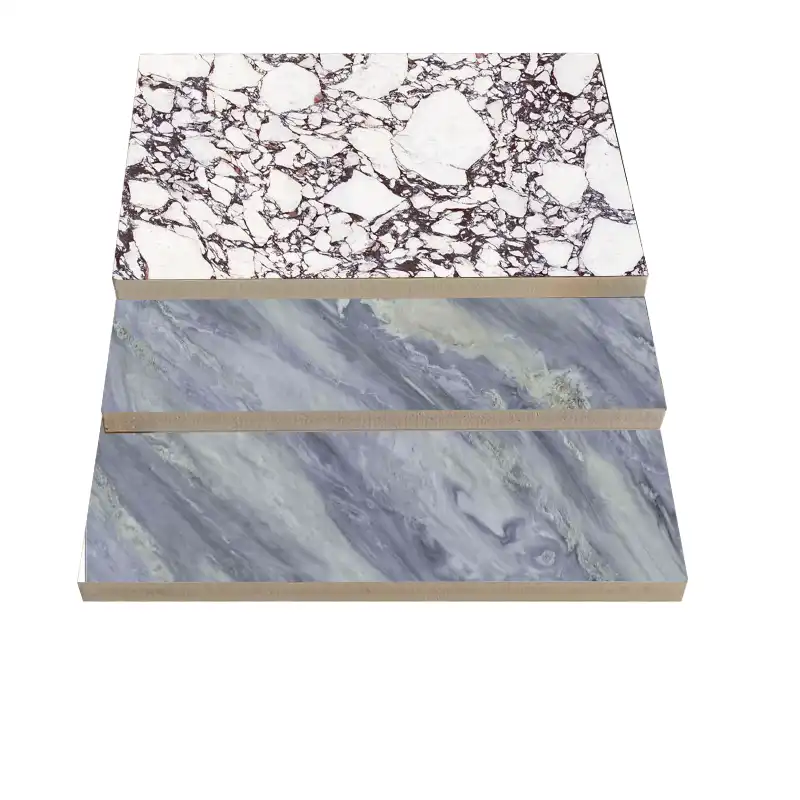

The 8mm PET film wood veneer is a big step forward in artistic surface technology. It is made by mixing PVC with calcium powder to make a strong hybrid material. The polyethylene terephthalate film layer keeps the look of real wood grain and makes the surface very durable. This hybrid building material stands up better to impacts and keeps its shape better than standard wood veneers. This makes it a great choice for business spaces where a lot of people are present.

The 8mm width standard is the best compromise between being bendable and keeping the shape. This size makes it easy to place in corners and along curves, and it is thick enough to avoid getting worn down or damaged. Adding calcium powder makes the material better at resisting fire, reaching the B1 fire resistance level according to global safety standards.

Environmental Benefits and Sustainability

These days, buying workers care more about products that are good for the earth, and PET film wood veneer is a good choice for this. This man-made wood veneer looks just as good as the real thing, but it is better for the earth because it doesn't require cutting down trees in wild forests. The material can be recycled, which is in line with green building projects and LEED approval standards that a lot of business projects now require.

The end product doesn't have any formaldehyde or volatile organic chemicals that could make the air inside worse, and the production process doesn't make much trash. These natural benefits make it especially appealing for home projects, healthcare facilities, and schools where the health of the people inside is still very important.

Why 8mm PET Film Wood Veneer Is a Preferred Choice for Projects?

Superior Durability and Performance Characteristics

When projects get tough, 8mm PET film wood veneer works better than other options, so project managers always pick it. The material shows great resistance to wetness, scratches, and contact damage that are common problems for real wood surfaces. Veneers made of melamine or paper can chip or delaminate when they are under a lot of stress, but PET film stays strong even in difficult conditions.

The installer's like how this material is easy to work with and always has the same high quality. Because it's cut so that every part of it is the same thickness and size, these wood panels won't bend or expand like wood goods that are natural. This dependability cuts down on work time and a customer's need to call back, which helps the project make money and keeps customers happy.

Versatile Application Across Industries

The 8mm PET film wood veneer can be used in many different kinds of projects and settings because it is so flexible. Commercial office buildings use this material for elevator cabs, welcome areas, and conference room wall panels where a professional look and long-lasting quality are important. The material's ability to stay looking brand new even after a lot of touching and cleaning is helpful in stores.

The material's ability to stay clean and be easy to take care of is especially important to healthcare centers. The non-porous surface can handle being cleaned often without getting worse and stops germs from growing. Schools like that this material doesn't get damaged easily and that it saves money in the long run compared to materials that need to be refinished or replaced often.

Comparing 8mm PET Film Wood Veneer with Alternative Solutions

Performance Analysis Against Traditional Options

When compared to standard wood veneer, 8mm PET film lasts longer and needs less upkeep. Wood is prone to water damage and surface scratches, and wood surfaces need to be refinished every so often. PET film wood veneer keeps its look during its entire service life, so it doesn't need to be treated or coated with a protection layer.

PET film has better edge sealing and pressure protection than plastic films. Because this material is flexible, it can be easily installed around complicated shapes without the cracking and breaking problems that happen with inflexible laminate goods. This adaptability lowers assembly difficulty and waste while enhancing the quality of the end product.

Economic Value and Total Cost Analysis

When procurement workers look at the total lifecycle costs, they know that 8mm PET film wood veneer is a great deal. Even though the materials cost more at first than some simpler options, they are cheaper in the long run because they don't need to be fixed and last longer. The material's initial order of 100 pieces works well for both small and big jobs.

The made-to-order production process lets you plan exactly how much you need to make, which lowers the amount of material wasted and store space needed. Custom color matching and pattern choices get rid of the need for various material specs, making it easier to get what you need and plan for installation.

How to Source and Procure 8mm PET Film Wood Veneer Efficiently?

Supplier Evaluation Criteria

Successful buying starts with a careful evaluation of the seller, focused on their ability to produce, quality standards, and reliable delivery. ISO9001, SGS, and CE approvals show that a company has a good method for managing quality and making sure products meet standards. These credentials give people peace of mind that the goods are in line with global norms and the needs of the project.

The 15-working-day delivery time for custom production needs careful planning and early selection of materials. To keep an eye on the progress of production and plan the shipping times with installation schedules, procurement teams need to make sure that they can talk to their sellers clearly.

Quality Assurance and Sample Evaluation

Before placing a full order, professional buyers usually ask for samples to make sure the materials are appropriate. Color correctness, surface roughness, and physical uniformity should all be tested in the sample assessment. To make sure that the project specifications are followed, the material's fire resistance grade and environmental safety paperwork should be looked at.

Regular boxes, pearl cotton security, and wooden cases are all different ways to package items so that they can be shipped to different places and meet different shipping needs. International shipments benefit from better safe packaging to keep them from getting damaged during long travel times.

Shandong Dingyue: Your Trusted Partner for Premium PET Film Wood Veneer

Industry Leadership and Manufacturing Excellence

Since 2009, Shandong Dingyue has been a top maker of artistic materials, putting health and environmental safety at the center of their work. Our manufacturing plant is 30,000 square meters in size, and more than 150 of the plant's production lines are built for making PVC ornamental panels and eco-friendly face materials. This large production capacity makes sure that big business projects always have the supplies they need, and it is still possible to make changes for unique needs.

Our R&D team is always coming up with new ways to make our products work better and be more eco-friendly. Adding flame safe, antibacterial, and formaldehyde-free technologies to our 8mm PET film wood veneer goods shows that we want to meet new industry standards and client demands.

Global Service and Support Capabilities

Dingyue knows what foreign markets need because their goods are sent to more than 60 countries in Europe, Southeast Asia, the Middle East, and the Americas. Our tailored product adaption makes sure that it meets the needs of different areas. For example, it gets CE and SGS certifications for the European and American markets and better moisture protection for use in warm temperatures.

Our all-inclusive service style offers expert advice, quick customer help, and easier organization of processes across countries. The ten-year quality promise shows that we believe the product will last and are committed to building long-term relationships with customers.

Conclusion

The 8mm PET film wood veneer is widely used in modern building because it works better, is better for the environment, and is more cost-effective. This new material meets the most important needs of buying professionals: it has to be durable, it must look good, it has to be environmentally friendly, and it has to be cheap. Putting PVC and calcium powder together makes a very fire-resistant and strong structure that keeps the look of natural wood that customers want.

As building codes continue to stress eco-friendliness and the health of people who live in them, 8mm PET film wood veneer is an innovative option that meets today's needs while also expecting future rules. The material has been used successfully in a wide range of settings, from businesses to hospitals, showing that it is reliable and works well in tough conditions.

Frequently Asked Questions

Q1: How does 8mm PET film wood veneer compare to real wood veneer when it comes to how much care each one needs?

A: An 8mm PET film wood veneer doesn't need to be taken care of as much as real wood. The man-made surface doesn't absorb wetness or spots, get scratched, or need to be refinished, sealed, or treated with protective chemicals every so often. Cleaning the wood with normal store-bought cleaners keeps it looking good without having to use specialized wood care products or hire an expert.

Q2: Can the 8mm PET film wood veneer be changed to fit the needs of certain projects?

A: Yes, our made-to-order process can match colors, change textures, and make things of certain sizes. The 100-piece minimum order makes it possible to customize the items for each job while still keeping the costs low for business use.

Q3: What certificates make sure that the 8mm PET film wood veneer items you sell are safe and of good quality?

A: Our goods have ISO9001, SGS, and CE certifications, which are proof that they meet global safety and quality guidelines. The B1 fire resistance grade and formaldehyde-free make-up meet strict building codes and "green" building material standards needed for today's construction projects.

Partner with Dingyue for Your Next Project

Change the way your next building project is done with high-quality 8mm PET film wood veneer from Dingyue, a maker and seller you can trust. Our ISO-certified factory and thorough quality checks make sure that the materials always work the way you need them to for your projects and meet your deadlines. Enjoy the benefits of working with a well-known company that knows how complicated foreign buying can be and offers dependable solutions for big projects. To talk about your needs with our tech team and check the quality of our materials, ask for samples today. For full product information, customization choices, and cheap prices for your future projects, email us at dingyue@dywpcpvcpanel.com.

References

1. Johnson, M. R. (2023). "Advanced Decorative Materials in Commercial Construction: Performance Analysis of Synthetic Veneer Systems." Journal of Building Materials Research, Vol. 45, No. 3, pp. 234-251.

2. Chen, L. & Anderson, K. (2022). "Fire Resistance Properties of PET Film Composite Materials in Architectural Applications." International Fire Safety Engineering Review, Vol. 28, No. 7, pp. 445-462.

3. Thompson, Sarah J. (2023). "Sustainable Building Materials: Environmental Impact Assessment of Synthetic Wood Alternatives." Green Construction Quarterly, Vol. 19, No. 2, pp. 78-94.

4. Rodriguez, Carlos M. (2022). "Cost-Benefit Analysis of Modern Veneer Systems in Large-Scale Commercial Projects." Construction Economics Review, Vol. 31, No. 4, pp. 156-173.

5. Williams, David P. & Kumar, Priya (2023). "Maintenance Requirements and Lifecycle Performance of Synthetic Decorative Materials." Building Maintenance International, Vol. 40, No. 5, pp. 289-305.

6. Liu, Wei & Peterson, James (2022). "Quality Standards and Certification Requirements for Import Building Materials in Global Markets." International Trade in Construction Materials, Vol. 15, No. 8, pp. 112-128.