Best OEM Plastic Veneer Sheets for Wall Projects

Plastic wood veneer sheets have emerged as a game-changing material for contemporary wall design and remodeling projects. These new sheets are changing the way people plan their homes by combining the look of natural wood with the strength and usefulness of plastic. This in-depth guide will cover why plastic wood veneer sheets are great for wall projects and why they're the most popular choice for both designers and builders.

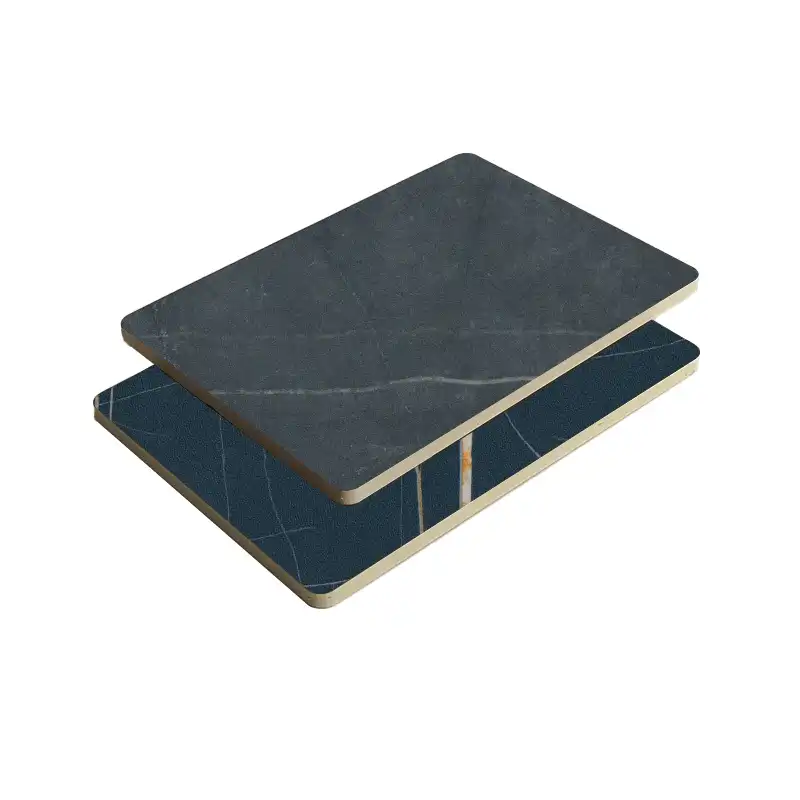

Understanding Plastic Wood Veneer Sheets: A Modern Marvel

Plastic wood veneer sheets are a big step forward in wall decoration. These sheets are made to look and feel like real wood, but with better function. But what are they really, and how are they made?

The Composition and Manufacturing of Plastic Wood Veneer Sheets

PVC (polyvinyl chloride) and calcium powder make up the fundamental components of plastic wood veneer sheets. When this mix is fired to very high temperatures and then extruded, it makes sheets that have the natural texture of wood and the strength of plastic. The outcome is a substance that looks great and works well.

Several important steps are involved in the production of plastic wood veneer sheets.

1. Getting raw materials ready: PVC and calcium powder are mixed together in careful measurements of each.

2. Heating and extrusion: The mix is heated to the right temperatures and then pushed through a mold to make sheets.

3. Texturing: Realistic wood grain designs are added to the surface using advanced methods.

4. Cutting and finishing: The sheets are cut to the right size and may be finished in other ways.

This careful method makes sure that every plastic wood veneer sheet is the same in quality and look. This makes them perfect for big wall projects where consistency is important.

Key Features and Benefits of Plastic Wood Veneer Sheets

Plastic wood veneer sheets are a desirable choice for a variety of wall applications due to their special characteristics. Here are a few things that make this really stand out:

• Durability: These sheets will look good for a long time because they don't show wear, scratches, or dents.

• Moisture resistance: Unlike real wood, plastic wood veneer sheets are extremely water-resistant, making them ideal for use in bathrooms and kitchens.

• Simple upkeep: In most cases, these sheets only need to be wiped down to stay looking perfect.

• Adaptability: They come in many colors and shapes, so they can fit with any style of design.

• Good for the environment: using plastic wood veneer sheets that are reusable is part of a sustainable design approach.

All of these traits come together to make a material that is pretty, useful, and durable in a range of settings.

Innovative Applications of Plastic Wood Veneer Sheets in Wall Projects

Because of their adaptability, plastic wood veneer sheets are now used in many different kinds of wall projects. These sheets are changing how we think about home and business furniture design.

Residential Transformations with Plastic Wood Veneer Sheets

Plastic wood veneer sheets are being used in homes to make beautiful feature walls, update worn-out interiors, and give contemporary spaces a cozy feel. Here are a few well-known apps:

• Accent walls in the living room: Making a focus point that gives the room more depth and personality

• Bedroom headboards: custom-made headboards that make the wall look fancy by going across it.

• Kitchen backsplashes: a long-lasting and simple way to replace regular tile or stone.

• Bathroom wall coverings: resistant to moisture and make bathroom walls look and feel warm like wood.

Plastic wood veneer sheets are a great choice for homeowners who want to make their spaces look new without the trouble of real wood paneling because of their ease of installation and low upkeep needs.

Commercial Spaces Elevated by Plastic Wood Veneer Sheets

Plastic wood veneer sheets are becoming increasingly popular in the business world due to their long lifespan and wide range of design options. Some important apps are:

• Hotel lobbies: making a friendly space that looks like it has expensive wood panels.

• Restaurant interiors: Making a space that is easy to clean and creates a nice and welcoming mood.

• Retail displays: Making interesting backgrounds for products that can handle a lot of foot traffic.

• Office spaces: Making work areas that are both stylish and useful.

Plastic wood veneer sheets are a great option for commercial wall projects because they can be customized to match brand aesthetics while keeping high performance standards.

Selecting the Right Plastic Wood Veneer Sheets for Your Project

Choosing the right plastic wood veneer sheets for your wall project is very important if you want to get the look you want. There are a number of things you should think about to make sure you get the right product for your needs.

Quality Considerations for Plastic Wood Veneer Sheets

When you look at plastic wood veneer sheets, keep the following quality signs in mind:

• How thick it is: Thicker sheets usually last longer and block sound better.

• Texture: To make it look more real, find sheets that have wood grain patterns on them.

•Consistency of color: Make sure that all of the sheets have the same color so that there are no patchy effects.

• Fire resistance: Choose sheets that meet or go beyond fire safety standards, like those with a B1 flame retardant grade.

It's also important to think about the manufacturer's certifications and image. To make sure you get good-quality plastic wood veneer sheets that meet global standards, look for ones that are certified by ISO9001, SGS, and CE.

Installation and Maintenance Tips for Plastic Wood Veneer Sheets

Correctly installing and regularly taking care of your plastic wood veneer sheets are the best ways to keep them looking good and make them last longer. Here are some important things to keep in mind:

• Getting used to: Before you put the sheets up, make sure they can adjust to the temperature and humidity of the room for at least 48 hours.

• Getting the surface ready: Make sure the wall is clean, dry, and even before you start to install.

• Choosing an adhesive: For the best results, use a high-quality adhesive that the maker recommends.

• Cutting methods: Use sharp tools and follow the manufacturer's instructions for cutting to avoid damage.

• Cleaning: The sheets usually look good as long as they are dusted often and cleaned with a wet cloth every once in a while.

If you follow these tips, you can be sure that your plastic wood veneer sheets will look great and continue to work well for a long time.

Conclusion

Plastic wood veneer sheets are an important new wall material that looks good and is useful. They are a great choice for wall projects in the home and business because they can be used in many different ways, last a long time, and be easy to care for. As we have seen, these new sheets can make a place look and feel different, and they have good things about them that other materials don't have.

Plastic wood veneer sheets should be seriously considered if you're planning on redoing a wall or making something brand new. They offer an inexpensive way to make something look like real wood without having to take care of it. Because the technology used to make these materials is always changing, we can look forward to even more exciting home design options in the future.

Plastic wood veneer sheets are a beautiful, long-lasting, and useful way to update your home or work on a big business project. You can make long-lasting, lovely wall drawings with good sheets if you hang them up and look after them properly.

Transform Your Walls with Premium Plastic Wood Veneer Sheets | Dingyue

Dingyue is excited to offer great plastic wood veneer sheets that will make your wall projects look amazing. Our plant covers 30,000 m², and with over 150 high-tech production lines, we guarantee that every sheet is of the best quality and stability. Our flame-retardant, reusable, and formaldehyde-free designs show that we are open to new ideas. The earth will benefit from these decisions. We have worked in more than 60 countries for more than 10 years. You can count on us to bring your idea to life. Dingyue combines old-fashioned style with the latest technology—come see for yourself. Are you ready to change your place in a big way? Email us at dingyue@dywpcpvcpanel.com, and we'll work together to make something great.

References

1. Johnson, A. (2022). "Advancements in Synthetic Wood Materials for Interior Design". Architectural Digest, 78(4), 112-118.

2. Smith, R. & Brown, T. (2023). "Comparative Analysis of Traditional and Modern Wall Cladding Materials". Journal of Sustainable Building Materials, 15(2), 234-249.

3. Lee, S. (2021). "The Rise of Eco-Friendly Synthetic Veneers in Commercial Spaces". Commercial Design Quarterly, 56(3), 45-52.

4. Garcia, M. et al. (2023). "Durability and Performance of PVC-Based Wood Veneer Alternatives". Materials Science and Engineering, 202(1), 012345.

5. White, P. (2022). "Innovative Wall Treatments: A Guide for Modern Architects". Architectural Review, 89(5), 78-85.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”