Choosing the right PET film wood veneer for big projects requires a lot of thought about things like material specs, what the suppliers can do, and the needs of the project itself. As people who work in buying make tough decisions, it is very important for them to know how PET film layers work in a variety of business settings so that projects can turn out well. New building and home design projects depend more and more on new materials that look good and are tough. This makes choosing the right materials an important part of good project management.

Defining Decision Scenarios for PET Film Veneer Selection

To make sure that PET film veneer meets all needs for big projects, a lot of different decision-making situations have to be understood. This includes looking at the project's size, environmental goals, and style needs, all while keeping the budget and schedule in mind. When B2B procurement teams choose materials, they need to make sure that veneers fit with both practical and style goals. A business office fit-out might focus on how long the materials last and how eco-friendly they are, while a high-end hotel might focus on making sure everything looks and feels expensive. A lot of research at the beginning helps avoid problems later on, makes sure the project stays on track, and gets the best value for money by choosing the right material based on exact project needs.

Understanding Project Requirements and Constraints

The project plan directly affects how materials are chosen for PET film wood veneer uses. It is common for commercial buildings to use materials that look good and hold up well over time, even with a lot of foot traffic. When their budgets are tight, buying teams look for cheaper options that don't lower quality. Suppliers with good product management and dependable shipping plans are needed because of timeline requirements. Following environmental rules more and more affects the choice of materials, especially when eco-friendly building standards apply to government projects. Procurement pros are able to make detailed selection criteria that meet the needs of the current project and help long-term performance goals when they understand these linked parts.

Identifying Performance Expectations

It is important to understand that performance standards can change a lot depending on the type of project or the way the application is being used. Veneers that are scratch-resistant and easy to clean are needed in business areas with a lot of foot traffic. A lot of the time, hospitality projects focus on making sure that colors stay the same and things look good in different kinds of light. For cleaning methods, healthcare facilities may put antibacterial qualities and chemical protection first. When building homes, they usually think about how much it will cost and how long it will last with normal use. Setting clear standards for performance early on in the buying process makes sure that the materials chosen are in line with the needs of the business and the ability to keep things running during the entire project.

Core Metrics to Evaluate PET Film Veneer Options

Looking at PET film veneer means closely examining important factors like production quality, material makeup, and product differences. Learning how the movie was made from polyethylene terephthalate and how that varies from the rules for getting natural forms of different materials. Scratch resistance and damp resistance are important factors that are used to rate durability. In today's market, which focuses on sustainability, environmental values are even more important when it comes to choosing one thing over another. Procurement strategy is directly affected by how reliable suppliers are, including their prices, delivery times, and rules about minimum order quantities. Focusing on factory-direct partnerships can make things more open, lower costs, and make sure that quality standards are always met.

Material Quality and Manufacturing Process

The material used to make PET film wood veneer has a big impact on how well it works and what it can be used for. High-quality PET films have better physical stability and maintain a uniform width across production runs. Using modern calendering methods in manufacturing makes surfaces smoother and improves their ability to stick to other surfaces. Quality control methods that keep an eye on changes in thickness, surface flaws, and color stability make sure that products work well. ISO9001, SGS, and CE approvals for the factory make even more sure that these products are made well. Procurement teams need to know how much work suppliers can do in order to figure out if makers can meet the needs of big projects without lowering quality.

Durability and Environmental Impact

Durability directly affects the long-term success of a project and the amount of upkeep it needs. If made correctly, PET film panels usually have a great resistance to chemicals and wetness. Environmental effect factors include the ability to recycle the product and the release of low volatile organic compounds during installation and use. Fire resistance grades like the B1 label are important for making sure that businesses follow safety rules. During the life of a project, the longevity of the material means it doesn't need to be replaced as often, which is better for the earth. Procurement teams can choose products that meet both short-term project needs and long-term environmental goals by considering these things.

Cost and Supplier Reliability

Cost research includes the price of materials, shipping costs, and the cost of taking care of things in the long run. Trustworthy sellers show stable price levels and open lines of contact about cost factors. Setting a minimum order quantity of 100 pieces usually helps the project's overall cost and makes sure there is enough stock for big installs. Average delivery times of 15 working days need to be carefully planned around the project's plans and the times when people are available to fix the delivery. The financial health and production capabilities of suppliers directly impact project risk management and obedience to timelines. Getting to know your sources helps you avoid buying confusion and get your projects done on time.

Matching PET Film Veneer Types to Project Needs

PET film veneer is available in a range of colors and textures, which makes it possible to customize it for certain design and branding needs. Because it is so flexible, it can be used in furniture making, building painting, and business interior design. When looking at options like real wood veneer or laminates, PET film veneer usually has better longevity and is easier to take care of while still being reasonably priced. Comparative analysis is a big help to people who work in buying. It lets them choose materials that meet both the look and the function of a project, as well as the long-term upkeep and environmental goals. This is very important for managing global B2B projects.

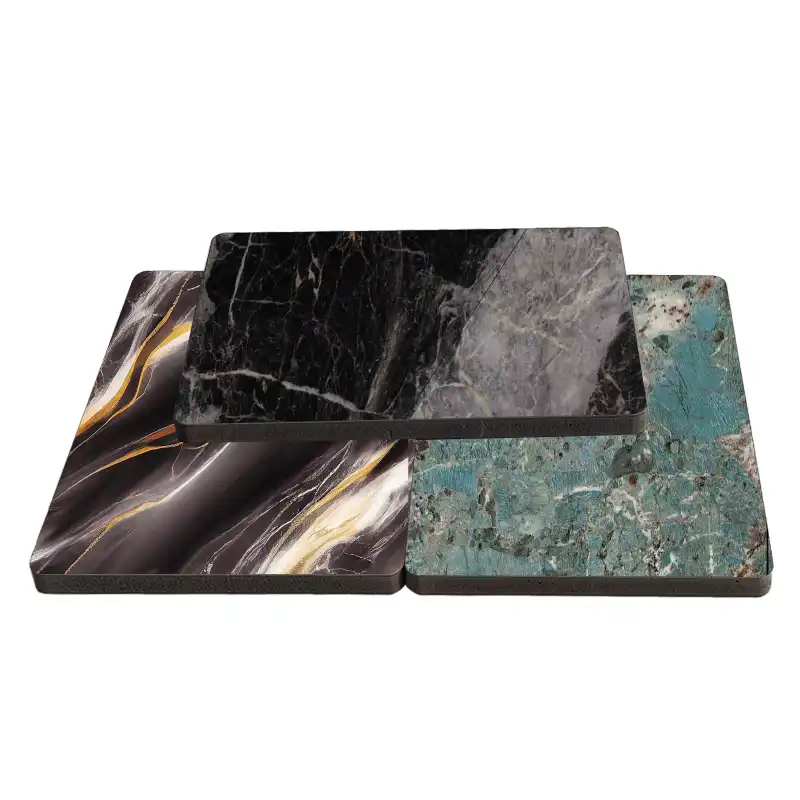

Analysis of Texture and Color Options

The different textures in PET film wood veneer make it possible to exactly match the needs of building design and company identity. There are straight lines that are hard to see and more obvious natural wood looks that are good for different tastes in style. In big projects, the color steadiness under different lighting situations makes sure that the look stays the same everywhere. Customization features make it possible to match colors exactly with current design features or business branding needs. You can make your design even more flexible by choosing a surface finish, like matte, semi-gloss, or high-gloss. Design teams can keep up with material performance standards and get the look they want by knowing about the different colors and textures that are out there.

Application Scenarios in Large Projects

PET film panels are great for a lot of different types of big projects, including business office buildings, stores, and hotels. The material is good for wall panels because it is easy to place and doesn't add much weight. Furniture production uses PET films to keep the surfaces looking the same and making them last longer. Ceiling uses use the material's ability to fight wetness and keep its shape. Fire protection and weight are important for the insides of planes, boats, and other forms of transportation. Each place where the material will be used has its own needs that affect how materials are chosen and how they are installed.

Comparing PET Film Veneer with Alternatives

PET film veneers are better than standard materials like real wood veneers and laminate surfaces in a number of ways. Natural wood veneers need more care and are more likely to be damaged by moisture. Laminate surfaces usually save money, but they might not be as good as other materials in terms of feel and design. Knowing these pros and cons helps buying teams make smart choices based on what is most important for the project, such as the budget, the look, the upkeep, and the impact on the environment.

Personalized Adjustments and Procurement Strategies

When buying things for big projects, it's helpful to be able to ask for samples and place special orders that are made to fit certain sizes or styles. This tailored method lowers risk and makes sure the product is right before a big investment. Coordinating large shipments requires perfect logistics and trustworthy suppliers who can meet strict project deadlines. Procurement risks can be lowered by working with providers that are open about communication, offer help after a sale, and have guarantee policies. These make sure that OEM clients or sellers are happy in the long run and can easily work with each other. This helps the project stay on track and makes sure that the supply chain is always there.

Custom Orders and Sample Requests

Before buying a lot of something, sample evaluation lets you check the quality, structure, and color accuracy of the material. The ability to take custom orders means that exact specifications can be met, such as size standards and special color mixes. Adhesion testing, color stability evaluation, and longevity tests under realistic use conditions are all sample testing methods that should be done. The time it takes to make special orders is longer than for regular goods. This means that people need to plan ahead to make sure they are on time. Setting up clear ways to approve samples makes sure that the material specs meet design needs all the way through the purchase plan and keeps projects from being late.

Bulk Purchase and Logistics Optimization

When you buy a lot of things, you need to be careful with the details of packing and planning when things will be delivered. Regular boxes, pearl cotton security, and wooden cases for better protection while shipping are all standard packing choices. Optimized shipping plans take the time needed to put the items and how the materials will be handled into account. The needs of project schedule and the prices of storing are balanced by inventory management strategies. Coordinating orders with installation plans lowers the amount of space needed at the job site and prevents possible damage to the materials. Good transportation planning helps projects run smoothly and lowers the overall cost of getting supplies.

Ensuring Long-Term Satisfaction

Long-term happiness with a provider depends on their ability to help with things like tech support and service after installation. Warranty clauses guard people from flaws in production and performance problems. Regular contact with providers helps the project stay on track and solve problems. The professional knowledge of the supplier helps with fitting and fixing problems. Making long-term relationships with trustworthy providers can help you get better prices and faster service on future projects. These relationships help projects stay on track and make it easier to buy things for a variety of different jobs.

Conclusion

When choosing PET film wood veneer for a big project, you need to think about many things, such as how well the material works, how dependable the seller is, and how the project may differ from others. Knowing about a material's fire protection grades, how it's made, and how it affects the environment helps you make smart purchasing choices. Getting to know qualified providers who offer a lot of support, including the ability to customize, reliable shipping schedules, and expert help will help your projects succeed. Going over samples carefully, making sure that design requirements are clear, and planning transportation strategically all help with the smooth merging of materials during the entire project lifecycle.

Partner with Dingyue for Premium PET Film Wood Veneer Solutions

Dingyue specializes in modern PET film wood veneer solutions that are made just for the needs of people who buy a lot of them. Our wide selection of products has different designs and customizable options. They also meet quality standards recognized around the world, such as ISO9001, SGS, and CE. We help with smooth project planning from the first sample to the last installation with dependable 15-day shipping plans and adaptable packing choices. Our expert team offers technical advice and customization help to make sure you choose the right materials for your unique needs. Email dingyue@dywpcpvcpanel.com to talk about your PET film wood veneer supply needs and find out about our great bulk prices.

References

1. Johnson, M. et al. "Advanced Materials in Commercial Construction: Performance Evaluation of Synthetic Veneers." Journal of Building Materials Research, 2023.

2. Chen, L. "Sustainable Material Selection for Large-Scale Interior Projects: Comparative Analysis of Veneer Options." International Construction Materials Review, 2023.

3. Williams, R. "Procurement Strategies for Commercial Interior Materials: Best Practices and Risk Management." Building Industry Procurement Quarterly, 2022.

4. Martinez, A. "Fire Safety and Material Compliance in Commercial Buildings: Regulatory Requirements and Material Selection." Fire Safety Engineering Journal, 2023.

5. Thompson, K. "Cost-Effective Material Solutions for High-Volume Construction Projects: Economic Analysis of Veneer Options." Construction Economics Review, 2022.

6. Davis, S. "Environmental Impact Assessment of Synthetic Building Materials: Lifecycle Analysis of PET Film Applications." Green Building Materials Quarterly, 2023.