Plastic Wood Veneer Sheets: Maintenance for Longevity

Plastic wood veneer sheets have revolutionized interior design, offering the timeless beauty of wood with enhanced durability and practicality. As a sustainable alternative to traditional wood veneers, these innovative materials are gaining popularity in both residential and commercial applications. However, to truly maximize their lifespan and preserve their aesthetic appeal, proper maintenance is crucial. This comprehensive guide will explore the best practices for maintaining plastic wood veneer sheets, ensuring they remain a stunning focal point in your space for years to come.

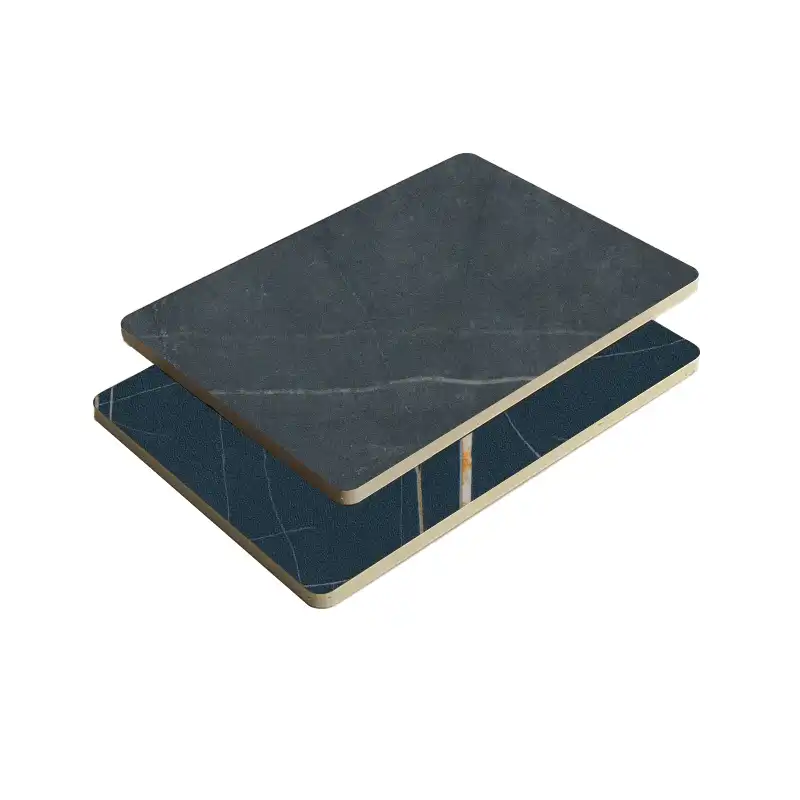

Introducing Plastic Wood Veneer Sheets

Before delving into maintenance techniques, it's essential to understand the unique properties of plastic wood veneer sheets. These versatile materials combine the natural look of wood with the resilience of synthetic polymers, resulting in a product that offers numerous advantages over traditional veneers.

Composition and Manufacturing Process

Plastic wood veneer sheets are crafted through an innovative process that fuses PVC and calcium powder. This fusion occurs under high temperature and pressure, creating a composite material that retains the organic texture and warmth of wood while benefiting from the durability of plastic. The manufacturing process allows for precise control over thickness, pattern, and color, resulting in plastic wood veneer sheets that can mimic a wide variety of wood species with remarkable accuracy.

Advantages Over Traditional Materials

The unique composition of plastic wood veneer sheets offers several advantages over traditional wood veneers and other decorative materials:

- Enhanced water resistance, making them ideal for high-moisture environments

- Improved durability and resistance to scratches, dents, and wear

- Greater color consistency and stability, reducing the need for frequent refinishing

- Easier installation and maintenance, saving time and labor costs

- Eco-friendly options available, contributing to sustainable design practices

Understanding these properties is crucial for implementing effective maintenance strategies that will preserve the beauty and functionality of plastic wood veneer sheets over time.

Common Applications

The versatility of plastic wood veneer sheets makes them suitable for a wide range of applications in both residential and commercial settings. Some popular uses include:

- Wall paneling and accent walls

- Ceiling treatments

- Commercial interiors such as hotels, restaurants, and offices

Regardless of the application, proper maintenance is key to ensuring that plastic wood veneer sheets retain their appeal and performance characteristics throughout their lifespan.

Essential Maintenance Techniques

Maintaining plastic wood veneer sheets is relatively straightforward, but it requires consistency and attention to detail. By following these essential maintenance techniques, you can significantly extend the life of your veneer and keep it looking pristine.

Regular Cleaning Routines

Establishing a regular cleaning routine is the foundation of proper maintenance for plastic wood veneer sheets. This not only keeps the surface looking fresh but also prevents the buildup of dirt and grime that can lead to long-term damage.

- Daily Dusting: Use a soft, dry microfiber cloth to gently remove dust and loose debris. This prevents particles from scratching the surface during more thorough cleaning.

- Weekly Cleaning: Dampen a soft cloth with warm water and mild soap. Wipe the plastic wood veneer sheets gently, following the grain pattern. Avoid using excessive water, as this can seep into seams or edges.

- Drying: Always follow wet cleaning with a dry, soft cloth to remove any remaining moisture and prevent water spots.

For stubborn stains or more thorough cleaning, consult the manufacturer's guidelines. Some plastic wood veneer sheets may be compatible with specialized cleaning products designed for synthetic materials.

Protecting Against Environmental Factors

While plastic wood veneer sheets are more resistant to environmental factors than traditional wood veneers, they still benefit from protective measures:

- UV Protection: Prolonged exposure to direct sunlight can cause fading or discoloration. Use window treatments or UV-resistant films on windows to minimize sun damage.

- Humidity Control: Although resistant to moisture, extreme humidity changes can affect plastic wood veneer sheets. Maintain consistent indoor humidity levels (30-50%) to prevent warping or separation.

- Temperature Regulation: Avoid exposing plastic wood veneer sheets to extreme temperature fluctuations, which can cause expansion and contraction.

By controlling these environmental factors, you can significantly extend the life and appearance of your plastic wood veneer sheets.

Preventive Measures and Best Practices

Implementing preventive measures can save time and effort in the long run, preserving the beauty of your plastic wood veneer sheets:

- Use Coasters and Mats: Place coasters under drinks and mats under plants or other items that may leave marks or moisture.

- Avoid Abrasives: Never use abrasive cleaners, scouring pads, or harsh chemicals on plastic wood veneer sheets. These can damage the surface irreparably.

- Prompt Spill Cleanup: Wipe up spills immediately to prevent staining or moisture penetration.

- Regular Inspections: Periodically inspect your plastic wood veneer sheets for any signs of damage, such as lifting edges or scratches. Addressing issues early can prevent more extensive damage.

By incorporating these preventive measures into your maintenance routine, you can ensure that your plastic wood veneer sheets remain in pristine condition for years to come.

Long-Term Care and Restoration

While regular maintenance can significantly extend the life of plastic wood veneer sheets, long-term care strategies and restoration techniques may be necessary to address wear and tear over time.

Addressing Minor Damage

Despite their durability, plastic wood veneer sheets can occasionally suffer minor damage. Here's how to address common issues:

- Scratches: For light scratches, try using a color-matched furniture marker or wax stick. Test in an inconspicuous area first.

- Dents: Some dents may be improved by applying heat with a hairdryer, causing the material to expand slightly. Use caution to avoid overheating.

- Edge Lifting: If edges begin to lift, carefully apply a small amount of adhesive recommended by the manufacturer and press firmly until set.

For more significant damage, it's best to consult with a professional or the manufacturer to explore repair or replacement options.

Refinishing and Restoration Techniques

Unlike traditional wood veneers, plastic wood veneer sheets generally don't require refinishing. However, if the surface becomes dull or shows signs of wear, consider these restoration techniques:

- Deep Cleaning: Use a specialized cleaner designed for synthetic wood products to remove built-up grime and restore shine.

- Polishing: Some plastic wood veneer sheets can benefit from a light polish with a product specifically formulated for synthetic materials. Always test in an inconspicuous area first.

- Professional Restoration: For extensive wear or damage, professional restoration services may be able to rejuvenate the appearance of plastic wood veneer sheets without replacement.

Remember that the specific restoration techniques suitable for your plastic wood veneer sheets may vary depending on the manufacturer and product line. Always consult the manufacturer's guidelines or a professional before attempting significant restoration work.

When to Consider Replacement

While plastic wood veneer sheets are designed for longevity, there may come a time when replacement is the best option. Consider replacement in the following scenarios:

- Extensive physical damage that compromises the integrity of the material

- Significant color fading or discoloration that cannot be restored

- Warping or separation that affects the overall appearance or functionality

- When updating the aesthetic of a space requires a new look

When considering replacement, explore the latest innovations in plastic wood veneer sheets. Manufacturers like Dingyue continuously improve their products, offering new textures, colors, and performance characteristics that may exceed your previous installation.

Conclusion

Plastic wood veneer sheets represent a significant advancement in interior design materials, offering the warmth and beauty of wood with enhanced durability and practicality. By implementing a comprehensive maintenance strategy that includes regular cleaning, environmental protection, and preventive measures, you can ensure that these versatile materials retain their beauty and functionality for years to come.

Remember that the key to longevity lies in consistent care and prompt attention to any issues that arise. With proper maintenance, plastic wood veneer sheets can continue to be a stunning and sustainable choice for your interior design projects, providing lasting beauty and value.

As technology and manufacturing processes continue to evolve, we can expect even more innovative and resilient plastic wood veneer sheets to emerge. Stay informed about the latest developments and maintenance techniques to make the most of these remarkable materials in your design projects.

FAQ

Q: What is wood plastic veneer?

A: It's an eco-friendly decorative material made by fusing PVC and calcium powder. It combines wood's natural texture with plastic's durability.

Q: What are its advantages over solid wood and tiles?

A: Compared to solid wood, it's waterproof, insect-resistant, and low-maintenance. Versus ceramic tiles, it offers a softer touch, quicker installation, and better slip resistance.

Q: Where is it mainly used?

A: It's used in living rooms, bedrooms, kitchens, bathrooms, balconies, basements, ceilings, and commercial spaces like restaurants and offices.

Q: Is it fire-resistant?

A: While not non-combustible, it meets China's B1 flame retardant standard, effectively delaying fire spread and offering better safety than ordinary wood.

Q: How do you ensure quality?

A: We conduct pre-production samples and final inspections before shipment to maintain high quality standards.

Choose Dingyue for Premium Plastic Wood Veneer Sheets | Your Trusted Manufacturer

When it comes to superior plastic wood veneer sheets, Dingyue stands out as a leader in innovation and quality. With over a decade of expertise, our state-of-the-art 30,000 m² production facility houses more than 150 advanced production lines, ensuring unparalleled product consistency and customization capabilities. Our commitment to sustainability and cutting-edge R&D has resulted in products that meet rigorous international standards, including CE and SGS certifications. Trust Dingyue to deliver eco-friendly, durable, and aesthetically pleasing plastic wood veneer sheets for your next project. Contact us at dingyue@dywpcpvcpanel.com to experience the difference that a dedicated manufacturer can make in your design endeavors.

References

1. Johnson, A. R. (2022). "Advanced Materials in Interior Design: The Rise of Plastic Wood Veneers." Journal of Sustainable Architecture and Design, 15(3), 78-92.

2. Smith, L. K., & Brown, T. E. (2021). "Maintenance Strategies for Modern Composite Materials in Commercial Spaces." Facilities Management Quarterly, 44(2), 112-125.

3. Zhang, Y., et al. (2023). "Comparative Analysis of Environmental Impact: Traditional Wood Veneers vs. Plastic Wood Composites." Environmental Science & Technology, 57(8), 3921-3935.

4. Patel, R. M. (2022). "Innovations in Wood-Plastic Composites: A Review of Recent Advancements." Progress in Polymer Science, 124, 101-118.

5. Miller, C. D., & Taylor, S. J. (2023). "Long-term Performance Assessment of Plastic Wood Veneers in High-Traffic Commercial Environments." Building and Environment, 209, 108-122.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”