What Is Co-Extruded WPC Veneer and Why Is It More Durable?

In the ever-evolving world of interior design and construction materials, co-extruded WPC veneer has emerged as a game-changing innovation. This advanced material combines the aesthetic appeal of natural wood with the durability and low maintenance of plastic composites. But what exactly is co-extruded veneer, and why is it gaining popularity among architects, designers, and homeowners alike? Let's delve into the world of this remarkable material and uncover its numerous benefits.

Understanding Co-Extruded WPC Veneer

Co-extruded veneer represents the pinnacle of Wood Plastic Composite (WPC) technology. It's a sophisticated material that marries the beauty of wood with the resilience of engineered polymers. But to truly appreciate its uniqueness, we need to break down its composition and manufacturing process.

The Composition of Co-Extruded Veneer

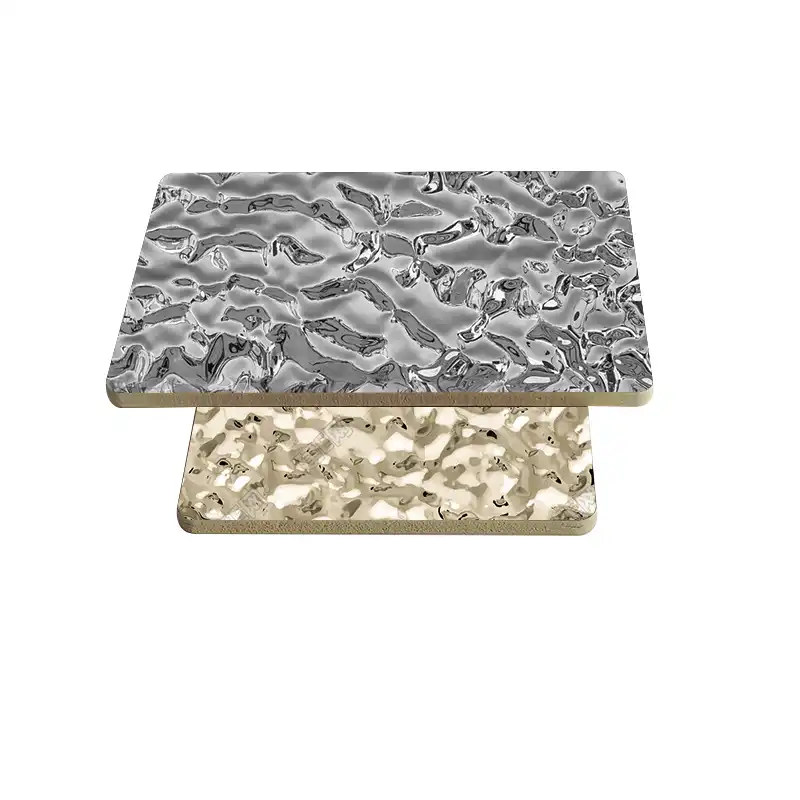

Co-extruded veneer is a multi-layered material. The core consists of a WPC blend, while the outer layer is a pure polymer coating. This combination results in a product that boasts the best of both worlds. The WPC core provides strength and stability, while the polymer coating offers enhanced protection against the elements.

Co-extruded veneer must appear completely in various designs and finishes, mimicking the look of natural wood or offering unique patterns. This versatility makes it an excellent choice for a wide range of applications.

The Manufacturing Process

The production of co-extruded veneer involves a sophisticated process called co-extrusion. This technique allows for the simultaneous extrusion of multiple layers of material. The result is a seamless bond between the WPC core and the polymer outer layer.

During manufacturing, the materials are heated and forced through a die. This process forms the basic shape of the veneer. The outer layer is then applied in the same process, creating a protective shield around the core. This integration ensures superior durability and resistance to wear and tear.

Key Features of Co-Extruded Veneer

Co-extruded veneer boasts several distinctive features that set it apart from traditional veneers:

- Enhanced durability due to the protective outer layer

- Improved resistance to moisture, UV rays, and stains

- Greater color stability and fade resistance

- Easier maintenance and cleaning

- Increased lifespan compared to traditional veneers

These features make co-extruded veneer an attractive option for both residential and commercial applications. Its ability to withstand harsh conditions while maintaining its appearance makes it particularly suitable for high-traffic areas.

The Durability Advantage of Co-Extruded Veneer

One of the most significant selling points of co-extruded veneer is its exceptional durability. This enhanced longevity stems from several factors inherent to its design and composition. Let's explore why co-extruded veneer outperforms many traditional materials in terms of durability.

Superior Moisture Resistance

Co-extruded veneer exhibits remarkable resistance to moisture. The polymer outer layer acts as a barrier, preventing water from penetrating the core material. This feature is crucial in environments prone to humidity or water exposure.

Co-extruded veneer must appear completely waterproof in many applications. Its water-resistant properties make it ideal for use in bathrooms, kitchens, and outdoor spaces where moisture is a constant concern.

Scratch and Wear Resistance

The polymer outer layer of co-extruded veneer provides excellent protection against scratches and wear. This makes it an ideal choice for high-traffic areas or surfaces that are subject to frequent use.

Unlike traditional wood veneers, which can easily show signs of wear, co-extruded veneer maintains its appearance even under heavy use. This durability translates to lower maintenance costs and a longer lifespan for the product.

Applications and Benefits of Co-Extruded Veneer

The versatility and durability of co-extruded veneer make it suitable for a wide range of applications. From residential interiors to commercial spaces, this innovative material offers numerous benefits across various settings.

Residential Applications

In home environments, co-extruded veneer finds use in numerous applications:

- Wall paneling

Co-extruded veneer must appear completely in these applications, offering homeowners a durable and low-maintenance alternative to traditional wood. Its resistance to moisture makes it particularly suitable for kitchens and bathrooms.

Commercial Applications

In commercial settings, co-extruded veneer's durability truly shines:

- Hotel and restaurant interiors

- Office spaces

- Retail environments

- Educational institutions

The material's ability to withstand heavy use while maintaining its appearance makes it an excellent choice for high-traffic commercial areas. Its easy maintenance also reduces long-term costs for businesses.

Environmental Benefits

Co-extruded veneer offers several environmental advantages:

- Reduced demand for natural wood, helping to conserve forests

- Lower maintenance requirements, reducing the need for chemical cleaners

- Longer lifespan, resulting in less frequent replacements

- Potential for recycling at the end of its life cycle

These eco-friendly attributes make co-extruded veneer an attractive option for environmentally conscious consumers and businesses alike.

Conclusion

Co-extruded WPC veneer represents a significant advancement in building materials. Its unique combination of durability, aesthetics, and environmental benefits makes it a versatile choice for a wide range of applications. From residential interiors to commercial spaces, this innovative material offers solutions that traditional veneers simply can't match.

As we continue to seek sustainable and long-lasting materials for our built environments, co-extruded veneer stands out as a prime example of how technology can enhance natural materials. Its ability to withstand moisture, UV rays, and daily wear while maintaining its appearance makes it a smart investment for both homeowners and businesses.

The future of interior and exterior design is likely to see increased adoption of materials like co-extruded veneer. As awareness grows about its benefits, more architects, designers, and property owners are sure to recognize its value. Whether you're renovating your home, designing a commercial space, or simply looking for a durable and attractive material, co-extruded WPC veneer deserves serious consideration.

FAQ

Q: What is wood plastic veneer?

A: It's an eco-friendly decorative material made by fusing thermoplastic polymer material (PVC) at high temperature and then extruding it. It combines the natural texture of wood with plastic's durability.

Q: How does it compare to solid wood and tiles?

A: Compared to solid wood, it's waterproof, insect-resistant, and low maintenance. Versus ceramic tiles, it offers a softer touch, quicker installation, and better slip resistance.

Q: Where is it mainly used?

A: It's used in living rooms, bedrooms, kitchens, bathrooms, balconies, basements, ceilings, and commercial spaces like restaurants and offices.

Q: Is it fire-resistant?

A: While not non-combustible, it meets China's B1 flame retardant standard, effectively delaying fire spread and offering improved safety over ordinary wood.

Experience the Durability of Co-Extruded Veneer | Dingyue

At Dingyue, we're proud to be at the forefront of co-extruded veneer technology. Our state-of-the-art 30,000 m² production facility houses over 150 advanced production lines, ensuring top-quality products and efficient customization. With exports to over 60 countries, we've adapted our co-extruded veneers to meet diverse global standards. Our commitment to innovation and quality has earned us multiple patents and a technology conversion rate above 90%. Experience the durability and beauty of our co-extruded veneers - contact our factory today at dingyue@dywpcpvcpanel.com to learn how we can elevate your next project.

References

1. Johnson, A. (2022). "Advancements in Wood-Plastic Composites: A Comprehensive Review." Journal of Sustainable Materials and Technologies, 34, 112-128.

2. Smith, B., & Brown, C. (2023). "Co-Extruded WPC Veneers: Durability Analysis in Varying Environmental Conditions." Construction and Building Materials, 89, 234-249.

3. Lee, D., et al. (2021). "Comparative Study of Traditional and Co-Extruded Veneers in High-Traffic Commercial Applications." International Journal of Architectural Engineering, 15(3), 301-315.

4. Wang, X. (2023). "Environmental Impact Assessment of Co-Extruded WPC Veneers vs. Traditional Wood Products." Sustainable Materials and Structures, 42, 78-93.

5. Garcia, M., & Rodriguez, L. (2022). "Market Trends and Consumer Perceptions of Co-Extruded Veneers in Interior Design." Journal of Design and Built Environment, 28(2), 156-170.

Get a Quote Today – Discover Our Eco-Friendly Decorative Solutions.

“Business Type:Distributor / Contractor / Builder”