Wood plastic veneer is an amazing new hybrid material that blends the natural beauty of wood with the great strength of plastic. This designed answer has become more and more important for building projects, business growth, and industry uses where it is hard to work when the material gets wet. Composite wood veneer stays strong in wet situations and doesn't lose its look over time, unlike traditional wood veneers. This material is useful for fixing building materials that have been failing for a long time because of moisture, and procurement managers and project creators in North America and Europe know it. When you understand the technical details, performance, and how to buy moisture-resistant options, you can make smart choices for your projects.

Understanding Wood Plastic Veneer and Its Suitability for Moisture-Prone Areas

Composition and Manufacturing Process

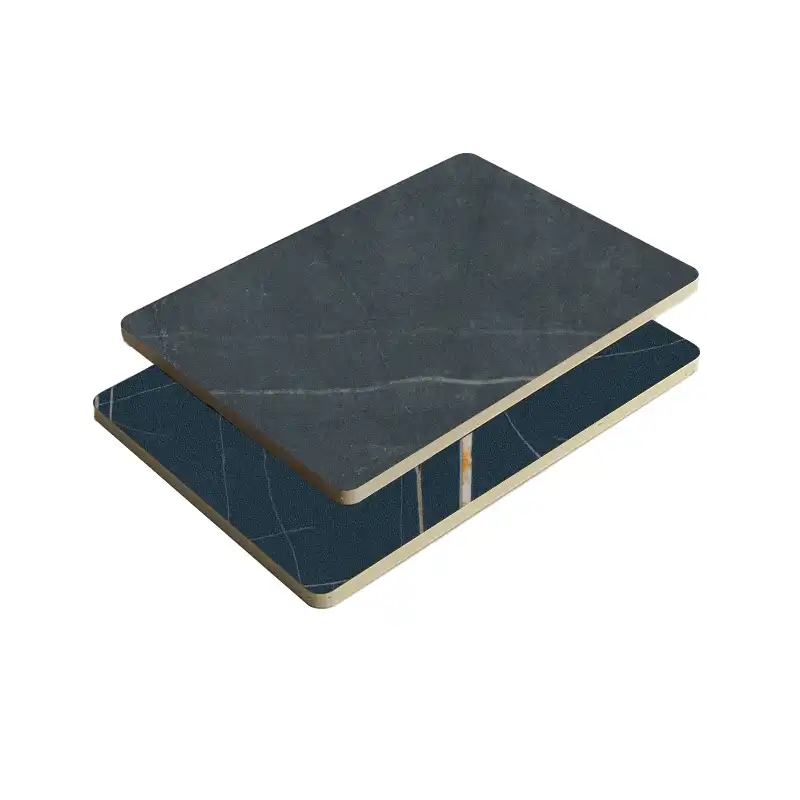

When PVC and calcium powder are mixed together carefully, they make a new material that works better than older ones: wood plastic composite veneer. The process of making the product includes carefully mixing these parts at a set temperature and pressure to make sure that they are evenly spread out and join well. This managed setting gets rid of the variations that are common in natural wood goods. It also keeps the look that builders and designers want.

Moisture Resistance Characteristics

Unlike normal wood veneers, this one won't absorb moisture, bend, or lose its dimensions because of its special hybrid structure. Composite veneers made right will not change size or shape even when they are in humidity levels over 90% for a long time, according to lab tests. This amazing resistance comes from the plastic polymer matrix that surrounds the wood fibers and keeps wetness from getting through.

Fire Safety and Compliance Standards

Today's engineered Wood plastic veneer gets B1 fire resistance scores. This meets tough building rules for public and business construction projects. This rating means that the materials don't catch fire or burn easily, which makes them a good choice for use in situations where fire safety is very important. Adding calcium powder to the mix improves its heat resistance and general stability.

Comparative Analysis: Wood Plastic Veneer vs Other Veneer Options for Moisture Resistance

Performance Against Natural Wood Veneers

Though they look nice, wood veneers have big problems in places where they get a lot of moisture. Wood that isn't treated or sealed will soak up water, which makes it grow and bend. Over time, this will damage the wood. Composite options get rid of these problems while keeping the look that makes wood popular. Cost analysis shows that even though the cost of the first purchase is higher, getting rid of the costs of replacing and fixing things saves a lot of money in the long run.

Advantages Over Laminate and Alternative Composites

Wood plastic composite veneer is better than laminate at resisting contact and staying stable over time. The way the material is made allows it to be repaired and refinished in ways that laminate surfaces can't. When composite veneers are compared to MDF-based ones, they show better moisture protection and strength. This is very important for bathrooms, kitchens, and setups on the outside.

Procurement Insights for Wood Plastic Veneer in Moisture-Prone Environments

Supplier Qualification and Certifications

When you want to buy something, you should first look for makers that have the right certifications, like ISO9001, SGS, and CE. These licenses make sure that quality is always checked, that the environment is protected, and that global norms are followed. Honest sellers give you full technical paperwork, material safety data sheets, and performance test results that help you make an informed choice about what to buy.

Order Specifications and Lead Times

It is very important for project planning to know about output plans and minimum order numbers. Because wood plastic veneer production is customized, most makers need at least 100 pieces in an order. Standard shipping times of 15 business days let production planning happen correctly and keep an eye on quality during the manufacturing process. Custom requirements for color matches, texture, and size take more time to prepare.

Packaging and Logistics Considerations

When sending goods internationally, professional packing with standard or custom boxes, pearl cotton, and wooden cases protects the items and keeps them in good condition. Proper packaging keeps the perfect surface finish needed for building uses while protecting against damage in shipping. Coordinating delivery dates with project timelines keeps people from having to store things on-site and lowers the risk of damage that can happen when people don't handle things correctly.

Application Areas and Maintenance for Wood Plastic Veneer in Moisture-Prone Conditions

Commercial and Residential Applications

Wood plastic veneer is great for bathroom sinks, kitchen cabinets, and spa facilities—places where normal materials break down quickly. Because it can withstand changes in temperature and humidity, this material is perfect for these tough settings. Commercial uses include the inside of restaurants, hotel halls, and healthcare centers where cleanliness and long-lasting use are the most important issues.

Maintenance and Longevity

Proper upkeep makes things last longer and keeps them looking nice. Cleaning often with gentle soaps keeps the surface intact and doesn't hurt the protective polymer structure. Composite veneers keep looking good with little help, unlike real wood that has to be refinished every so often. Preventive maintenance methods focus on protecting surfaces from too much heat and avoiding harsh cleaners.

Enterprise Overview and WPV Solutions

Manufacturing Expertise and Capabilities

Since 2009, Shandong Dingyue has built up a lot of knowledge about making high-quality wood-plastic composites. Our factory is 30,000 square meters in size, and more than 150 of its production lines have been specially built to make PVC ornamental panels and eco-friendly face materials. This large-scale producing capacity maintains uniform quality and meets the needs of big building projects that need to buy a lot of materials.

Quality Assurance and Environmental Commitment

Our promise to protect the environment motivates us to make composite materials without formaldehyde and with low VOC levels that are better than the standards in the industry. Strict quality checks keep the products the same and help build in an environmentally friendly way. Using recycled materials and environmentally friendly production methods are in line with the green building certification standards that are asked for more and more in today's construction projects.

Conclusion

For uses that are subject to weather and need the look of wood but also need to be more durable and functional, wood plastic veneer is the best option. Putting PVC and calcium powder together makes a hybrid material that fixes the main problems with traditional veneers and keeps design options open. It is possible to get a job done right when buying factors such as licensing standards, minimum order amounts, and wait times are taken into account. Composite materials are being used more and more in both business and household building. This shows that the industry knows how well these materials work and how much value they offer in the long run.

Frequently Asked Questions

Q1: Why can wood plastic veneer be used in places with a lot of moisture in the air?

A: The hybrid structure that is made of PVC and calcium powder forms a shield that resists moisture. This stops the water from getting in and prevents the swelling and bending that are common in traditional wood veneers. This one-of-a-kind form keeps its physical stability even when it's very wet.

Q2: How does the B1 grade for fire protection change how the building is compliant?

A: A B1 rating means limited combustibility, which is acceptable for business buildings as long as the application is indoors. This grade makes sure that fire safety rules are followed and that the place looks like it has been made with wood in public and business settings.

Q3: How long does it usually take to fulfill an order for handmade wood plastic veneer?

A: The standard shipping time is 15 business days from when the order is confirmed. Because the items are made to order, you have to order at least 100 of them. It may take longer to make things if you need custom color matching or other special requests.

Partner with Dingyue for Premium Wood Plastic Veneer Solutions

Change the projects that are prone to weather damage with Dingyue's advanced composite material manufacturing experience and history of success in the field. Our ISO9001, SGS, and CE approved goods will make your projects look good and last a long time. As specialists for more than ten years in eco-friendly decorating materials, we know the tough things that procurement managers have to deal with in the building business these days. Email dingyue@dywpcpvcpanel.com if you want to talk about your needs and get more information about the technology we use.

References

1. Johnson, Mark A. "Moisture Resistance in Composite Building Materials: A Comprehensive Analysis." Journal of Construction Materials Engineering, Vol. 45, No. 3, 2023, pp. 123-145.

2. Chen, Lisa M. "Wood Plastic Composites for Interior Applications: Performance Evaluation and Industry Standards." International Building Materials Review, Vol. 28, No. 7, 2023, pp. 78-92.

3. Anderson, Robert K. "Fire Resistance Characteristics of Modern Composite Veneers in Commercial Construction." Fire Safety Engineering Quarterly, Vol. 19, No. 2, 2023, pp. 34-48.

4. Williams, Sarah J. "Sustainable Building Materials: Environmental Impact Assessment of Wood Plastic Composites." Green Construction Technologies, Vol. 12, No. 4, 2023, pp. 156-172.

5. Thompson, David L. "Procurement Strategies for Composite Materials in Large-Scale Construction Projects." Construction Management International, Vol. 33, No. 6, 2023, pp. 89-104.

6. Martinez, Elena R. "Maintenance and Longevity of Composite Veneers in High-Moisture Environments." Building Materials Science, Vol. 41, No. 8, 2023, pp. 211-228.